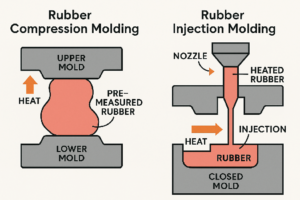

Rubber parts usually start as soft, hot material. In compression molding, you press a pre‑measured chunk between heated dies and let it cure. It’s simple and great for thick or low‑volume parts. Injection molding pushes heated rubber through a nozzle into a closed mold, filling every corner fast. That method handles complex shapes and higher production rates.

Think of compression vs. injection molding like using a waffle iron by hand vs. a batter dispenser. Both shape the same mix in different ways. This article will help manufacturers choose the most appropriate molding method from compression vs. injection molding.

Table of Contents

ToggleWhat is Rubber Compression Molding?

Compression molding shapes rubber while placing a pre-measured amount of rubber material into a heated mold cavity. Subsequently, the mold gets closed, and pressure is applied to force the rubber to fill the mold’s shape. Heat and pressure are upheld for a set time to cure the rubber. Once cured, the mold is opened, and the part is removed. Compared to other methods, compression molding is simpler and used when large or basic rubber parts are needed.

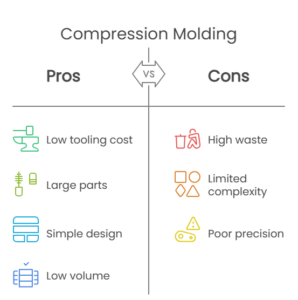

Typical Properties and Limitations

- Suitable for low to medium production volumes.

- Good for large or bulky parts.

- Simple mold design.

- Lower tooling cost.

- Less precise part tolerances.

- Higher material waste.

- Limited part complexity.

Common Applications

Compression molding creates seals, gaskets, bumpers, and large rubber components. It outfits parts that don’t need tight tolerances or shapes. When comparing compression vs. injection molding, compression is picked for lower-volume jobs or when the material being used is difficult to inject. It fits well for industrial parts where durability matters more than fine detail.

What Is Rubber Injection Molding?

Rubber injection molding starts with an uncured elastomer that is pre‑heated and pushed by a screw or ram into a heated, closed mold, where it flows through narrow runners and gates, then vulcanizes under high pressure. The process looks a lot like plastic injection molding; nevertheless, the rubber typically remains relatively cool until it enters the cavity, needs extra dwell time for cross‑linking, and the screw concentrates on moving volume rather than melting pellets. The main debate often centers on compression vs. injection molding when shops weigh cycle speed against tooling cost.

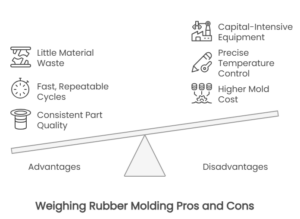

Advantages and Disadvantages

- Consistent part quality.

- Tight tolerances.

- Fast, repeatable cycles.

- Little material waste.

- Easy automation.

- Higher mold cost.

- Requires precise temperature control.

- Equipment is capital‑intensive.

- Not ideal for very large parts.

Typical Use Cases

You’ll see it wherever high elasticity and precise dimensional control matter—automotive door and window seals that keep out dust and noise, medical components like syringe plungers that must stay sterile, and tiny precision bits for electronics or valves that demand rubber’s flex without crack.

Compression vs. Injection Molding: Key Differences

Having examined compression molding and injection molding separately, we now turn to a direct comparison of their key characteristics. This side-by-side analysis highlights the fundamental differences to guide the selection of the most appropriate process based on specific manufacturing requirements.

Factor | Compression Molding | Injection Molding |

Cycle Time | Longer cycles (a few minutes) due to manual loading and curing processes. | Shorter cycles (a few seconds for thin-walled parts) owing to automation and rapid cooling. |

Tooling Cost | Lower initial tooling costs because of simpler mold designs. | Higher upfront tooling costs due to complex molds with runners and cooling systems. |

Material Waste | Higher waste from excess material and flash with uneven distribution. | Minimal waste; precise material injection lowers excess, and scrap is recyclable. |

Complexity of Parts | Best suited for simple, thick-walled, or flat parts; limited capability for complex features. | Ideal for complex geometries, thin walls, and detailed features with tight tolerances. |

Production Volume Suitability | Cost-effective for low to medium volumes and larger parts. | Efficient for high-volume production due to automation and speed. |

Upgrade Your Rubber Production with Dekuma

Paired with the right machinery, rubber injection molding offers unmatched precision. At Dekuma, we deliver high-quality rubber injection molding machines that combine advanced technology with durability to transform your production output.

Whether you’re scaling up production or fine-tuning complex parts, our RA Series and RV-SE Series rubber injection molding machines are sure to match your manufacturing goals.

The RA Series is a high-performance rubber injection molding machine specifically optimized for silicone rubber and EPDM, ideal for producing precision high-voltage components like insulators and cable accessories. Its energy-efficient design, advanced hydraulic system, and B&R-controlled precision ensure reliable, high-quality output.

For auto applications, our RV-SE Series machines are equipped with energy-efficient servo systems that only consume 40% of the electricity used by conventional machines. In addition to quiet operation and real-time power monitoring, the RV-SE also assures repeatability and swift dynamic response for TPV and TPE.

Regarding compression vs. injection molding, our injection systems provide better control over molding parameters for product stability and decreased cycle times. With such machines in your production line, you can realize higher throughput and product quality and lower active costs.

Conclusion

Choosing between compression vs. injection molding comes down to part size, volume, and precision: compression suits bulky, low‑to‑medium runs with simpler tooling, while injection handles tight‑tolerance, high‑volume parts quickly with less waste.

Dekuma’s RA and RV‑SE machines cover both needs with high clamping force, energy‑efficient servo drives, and precise pressure control. Along these lines, if you’re weighing upgrades for rubber production, it’s worth a closer look at how Dekuma machines could shorten cycles, trim scrap, and boost consistency.