- Yinzhu Road, Zhouwu Industrial Park, Dongcheng District, Dongguan City, Guangdong Province, China.

- Email:info-rim@dekuma.com

- Tel: +86-769-22667207

- Mobile: +86-15622909600

The first company in China's machinery industry to obtain reliability certification.

Dekuma manufactures rubber machines engineered to German technical standards, ensuring consistent performance and long-term stability.

Our experienced engineering and after-sales teams provide reliable support for your machines.

Founded in 2004, Dekuma specializes in turnkey rubber injection molding solutions for global customers. With advanced technology and responsive, professional service, we help global clients maximize value across industries such as automotive, power generation, rubber tracks, construction, and more.

After 20+ years of growth, Dekuma has built a strong international presence across Europe, the Americas, the Middle East, and Southeast Asia. Our customized equipment stands out for its superior quality and performance—making us a trusted partner among rubber injection molding machine manufacturers worldwide.

Dekuma ranks #1 among China’s rubber injection machine manufacturers in the sales of large-capacity models. With enduring partnerships with world-renowned rubber and plastic equipment brands, our solutions are trusted by clients across dozens of countries worldwide.

Dekuma enjoys a fruitful collaboration with SHEMAR, a renowned Chinese manufacturer of composite insulator, consistently delivering value through a trusted partnership.

Dekuma is proud to work with ZC RUBBER, a prominent Chinese manufacturer of rubber tracks, driving innovation through a strong and mutually beneficial partnership.

Dekuma's successful partnership with CHANGLAN, a prominent Chinese manufacturer of rubber cable accessories, drives value and growth through a strong, collaborative relationship.

Proven turnkey solutions. Trusted rubber machine manufacturer. Chosen by customers worldwide.

As a dedicated rubber injection molding machine manufacturer, Dekuma designs and produces all core components in-house. Supported by a full team of experts, Dekuma delivers tailored solutions to meet the diverse needs of customers worldwide.

Automotive Industry

Dekuma’s RV, RV-Se, and RC series rubber injection molding machines are widely used in the automotive industry。

These machines feature high injection pressure, minimal rubber leakage, stable hydraulic systems with low oil leakage, excellent mold locking and pressure retention, and reliable electronic control systems—qualities expected from top-tier injection molding equipment manufacturers.

Power Industry

Dekuma’s RA, RT, and RI series rubber injection molding machines are widely used in the power industry. We stand out among rubber molding machine suppliers thanks to the excellent characteristics of our machines. These include outstanding mold locking and pressure retention, large injection volume, high feed capacity, minimal air bubbles, low oil leakage in the hydraulic system, and consistent color integrity.

These machines offer excellent mold locking and pressure retention, large injection volume, high feed capacity, minimal air bubbles, low oil leakage in the hydraulic system, and ensure that products maintain their color integrity.

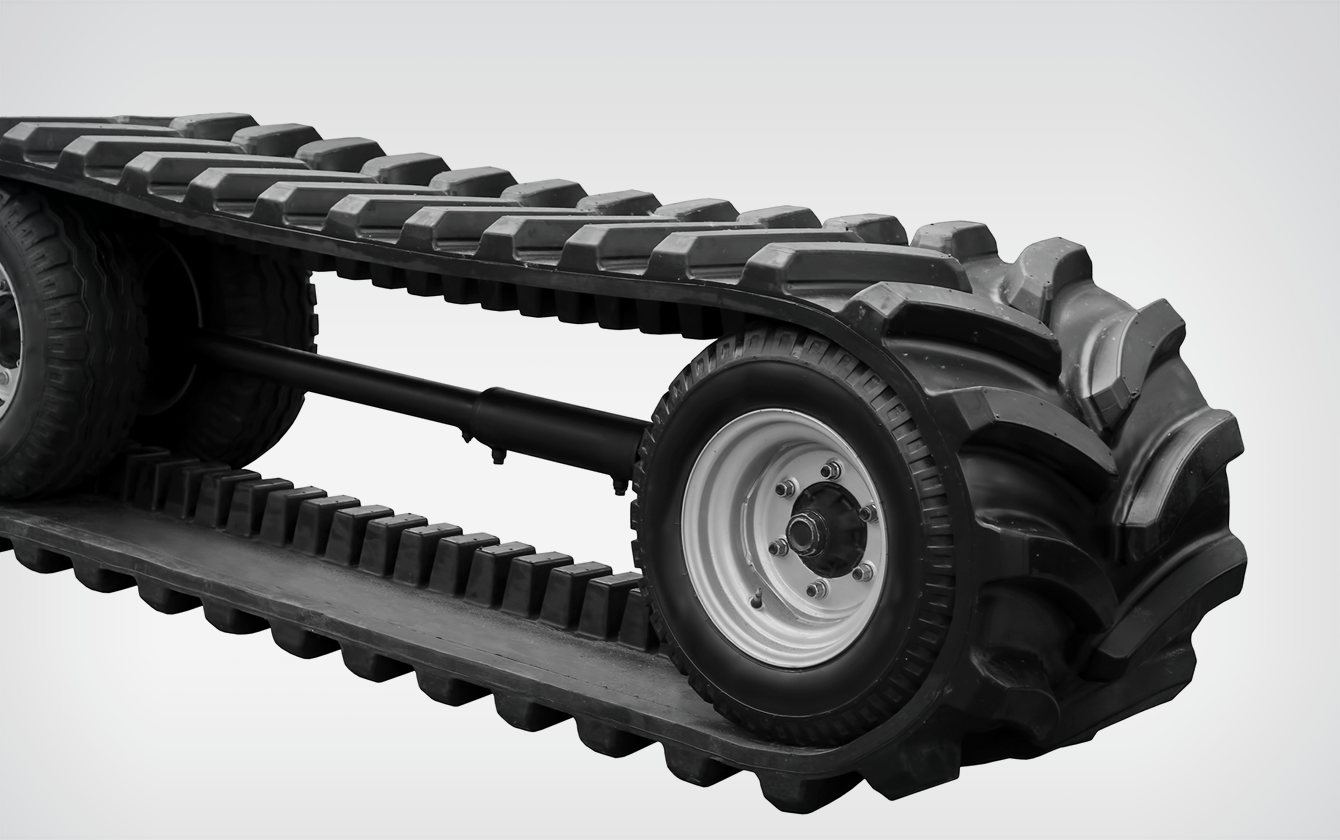

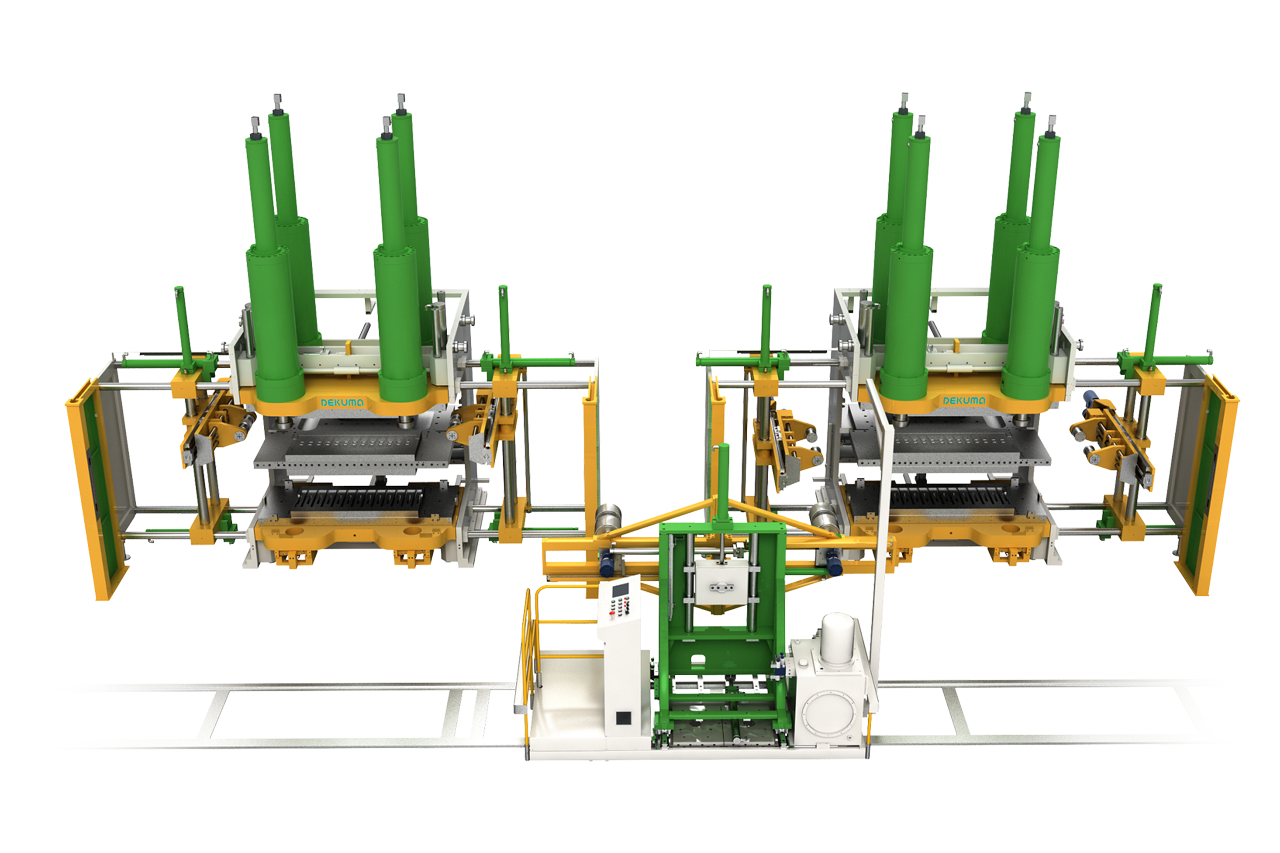

Rubber Track Production

Dekuma’s rubber track machines are utilized in a variety of industries, namely construction vehicles, military vehicles, and agricultural machinery.

These machines reflect Dekuma’s expertise among China’s rubber injection molding machine suppliers, featuring high automation, superior product quality, energy efficiency, environmental friendliness, and advanced, intelligent programming.

Other Industries

Dekuma’s RH and LSR series specialized machines are capable of producing a wide range of silicone rubber products. As an experienced injection molding machine maker, Dekuma provides machines recognized for their mature technology, high automation, precise metering, high efficiency, and excellent product quality.

These machines are known for their mature technology, high automation, precise metering, high efficiency, and excellent product quality.

Dekuma focuses on manufacturing rubber injection molding machines defined by ultra-large size capability, high precision, high efficiency, intelligent operation, automation, and specialization. This strategic direction is underscored by the 30+ national patents Dekuma has secured in China to date.

The DKM-RV series is widely used in the automotive industry, power industry, civil industry and other fields.

RV-Se series machines are widely used in the automotive industry. They are suitable for use with TPV, TPE, flexible modified PVC and other raw materials manufactured by injection molding.

The DKM-RC series is used for precision rubber parts, sealing strip joints, seals, skeleton oil seals, and TPU products.

Can process silicone rubber and Ethylene Propylene Diene Monomer (EPDM) to produce hollow core insulators, long rod insulators, surge arresters, cable accessories, and switchgear.

Suitable for use with HTV silicone rubber to produce long-rod insulators, hollow core bushings, arresters, cable accessories, and switchgear.

Suitable for general insulators and rubber products.

Designed for one-piece TPV automotive window sealing with precise injection control and large overall dimensions.

Suitable for agriculture tracks, constrution tracks, military tracks and snowmobile tracks.

Suitable for sealing rings and other rubber parts made of natural rubber, nitrile rubber, or fluoro rubber.

Suitable for electronic components, insulators, arresters, cable accessories, sealings, infant care products, food containers, kitchen articles, sport industry products, etc.

Dekuma goes beyond manufacturing high-quality rubber machines. Our turnkey solutions combine advanced machinery with a dedicated focus on customer satisfaction, expert support, and tailored approaches, ensuring your business can reach its full potential.

We establish comprehensive customer profiles and offer personalized consulting and guidance services through our proactive follow-up system, ensuring continuous support and satisfaction.

We maintain a streamlined spare parts service, ensuring that you receive necessary components quickly and accurately, minimizing downtime and keeping your operations on track.

Our 24/7 dedicated hotline is available year-round, connecting you with maintenance experts ready to respond to your needs at any time, ensuring you have support whenever you need it.

Our dedicated service engineers conduct regular on-site inspections, providing thorough preventive maintenance to keep your equipment running at peak performance.

We offer customized training programs designed to meet the specific needs of your team and operations, empowering your professionals with the skills they need to succeed.

We not only value each service interaction but also continuously improve and optimize our service processes through a proactive feedback mechanism, ensuring that every need you have is promptly addressed and resolved.

Dekuma’s rubber machines and services are trusted and recognized worldwide.