Rubber injection molding machines function to create precise, durable parts through pressure-driven molten rubber injection into molds. The manufacturing process serves multiple industries that need high-precision parts, including the automotive, medical, and electronics sectors. The following article presents three top injection molding machine manufacturers, which will assist you in selecting your ideal production partner.

Table of Contents

ToggleThe 3 Best Rubber Injection Molding Machine Manufacturers

1. Dekuma

For over 20 years, Dekuma has been devoted to designing, manufacturing, and marketing high-performance rubber injection molding machines. Its products serve customers in Europe, America, the Middle East, and Southeast Asia.

As a trusted industry partner, Dekuma offers comprehensive turnkey solutions for world-leading rubber and plastic equipment brands, including SINOTRUK, DRB, CYG, ABB, Elsewedy Cables, ZC Rubber, and Soucy International Inc.

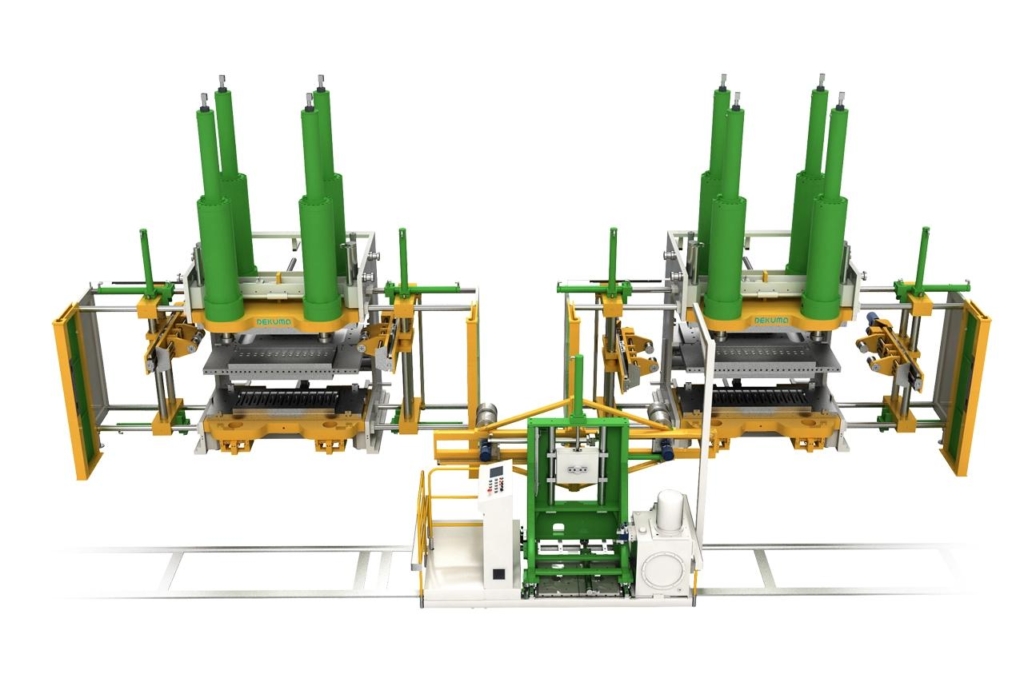

(Dekuma offers reliable, high-performance rubber track molding machines)

Dekuma supplies a full range of rubber injection molding machines. Based on the application fields, Dekuma’s rubber injection molding machines can be generally categorized as follows:

The RV Series, RV Se Series, and RC Series are widely used in automotive parts manufacturing. These machines can process a variety of rubber materials, such as natural rubber, nitrile rubber (NBR), EPDM, and butyl rubber. Typical products include rubber dampers, cylinder gaskets, sealing components, and cable connectors.

The RA Series, RT Series, and RI Series are mainly applied in the power sector. They are suitable for processing materials like silicone rubber and EPDM. Commonly produced items include hollow core insulators, rod insulators, lightning arresters, cable accessories, and switchgear components.

- Specialized Injection Molding Machines (Based on Product or Material):

Dekuma also offers specialized models tailored for specific materials or products. For example, the RH Series is designed for producing sealing rings using natural rubber, nitrile rubber, or fluororubber. In addition, Dekuma provides solutions for liquid silicone rubber (LSR) applications, ideal for manufacturing infant care items, food containers, insulators, and other precision silicone products.

If you are interested, feel free to contact Dekuma here!

2. US Molding

Since 1980, US Molding has been a trusted name in rubber injection technology. This US-based enterprise primarily designs and manufactures new, custom, or refurbished rubber injection molding machines serving the rubber products industry.

Their equipment focuses on durability through its solid steel frames and robust construction, which results in minimal deflection and near-zero flash parts. They are applied in various industrial sectors, including automotive manufacturing, energy production, pharmaceutical operations, and consumer product manufacturing.

3. Desma

DESMA is a global leader in the design and manufacture of injection-molding machines for elastomer applications. Specializing in turnkey solutions, the company integrates machine manufacturing, mold building, and automation engineering to serve sectors such as automotive, energy distribution, and medical technology.

With deep expertise in rubber and silicone processing, DESMA offers both vertical and horizontal injection systems along with cold-runner technology, providing high-precision, efficient, and resource-saving production for complex elastomer parts.

How to Choose the Right Rubber Injection Molding Machine Manufacturer

Choosing the right rubber injection molding machine manufacturer requires evaluation based on specific criteria.

1. Check Technical Expertise and Machine Specifications

The manufacturer’s technical know-how and the specific capabilities of their machines must align perfectly with your production needs. Consider whether you need vertical or horizontal injection molding machines. Furthermore, electric machines generally offer greater precision, energy efficiency, and repeatability, while hydraulic systems often provide higher clamping forces.

Your ideal manufacturing partner offers machines that meet your expectations in aspects including:

- Clamping Force (Tonnage): Must be sufficient to keep your molds closed against injection pressure to prevent “flashing” (excess material leakage).

- Injection Capacity (Shot Size): The volume of material the machine can inject per cycle must be adequate for your part and runner system volume.

- Platen Size and Tie-Bar Spacing: Must be large enough to physically accommodate your mold.

- Injection Pressure and Speed: Critical for filling complex molds or processing high-viscosity rubber materials.

- Specialized Capability: Look for expertise in specific rubber processes like Liquid Silicone Rubber (LSR), multi-component molding (2K/3K), or machines optimized for small shot weights (e.g., O-rings or seals).

- Control System: The machine’s control system (HMI/CNC) should be user-friendly, provide precise control over critical parameters (temperature, pressure, speed), and offer robust data logging and diagnostics.

2. Evaluate Rubber Injection Molding Machines’ Quality and Reliability

Machinery quality plays a crucial role in achieving consistent production results over time. Confirm that the manufacturer holds the necessary certifications or patents for rubber injection molding machine fabrication. This is fundamental to ensuring that supplied machines comply with your production standards.

Dekuma holds over 30 national patents and delivers machines that excel in speed, pressure, and temperature control, ensuring consistent and reliable performance.

For instance, Dekuma’s RA series follows strict German standards, with Austrian B&R control ensuring 0.05% theoretical precision, top-tier hydraulics, and enhanced screw design—delivering consistent molding, exceptional reliability, and approximately 40% energy savings for high-voltage rubber insulator manufacturing.

3. Analyse Total Cost and Value

While the initial investment in machinery is substantial, it is equally important to account for the costs incurred during setup and trial runs, ongoing maintenance once the equipment is operational, as well as energy usage over time.

Trusted manufacturers typically offer comprehensive guidance and support throughout each phase, helping users to maximize the machine’s capabilities and achieve their production goals. Below are key considerations and recommendations:

- Total Cost of Ownership (TCO): Evaluate all long-term expenses linked to the equipment, such as upkeep, power consumption, and potential downtime, to gain a clear picture of its overall cost.

- Maintenance Ease: Choose equipment designed for durability to reduce the frequency and complexity of servicing and repairs. Components should be readily disassembled, and manufacturers must provide efficient support services to reduce downtime and repair costs.

- Seek energy-efficient equipment that lowers consumption without compromising performance.

4. Enquire Service, Support, and Training

Select a manufacturer that delivers reliable after-sales support, ensures the availability of spare parts, and offers structured maintenance services.

Comprehensive training for your staff is equally crucial—effective instruction enables operators to minimize production mistakes and avoid unnecessary downtime. Companies that prioritize customer education and respond promptly to service requests contribute to smoother operations and improved output.

5. Consider Geographic Location and Automation Features

The manufacturer’s geographical proximity can directly influence shipping costs, lead times, and the ease of scheduling service or maintenance. Choosing a local supplier or one with nearby offices often results in faster, more affordable support, enabling quick resolutions and lowering travel expenses.

As injection molding continues to embrace automation and smart technology, it is advantageous to seek manufacturers who can integrate machines with robotics and IoT systems. Opt for those who offer robust data solutions for real-time monitoring and process optimization, empowering you to advance your goals for smart manufacturing.

6. Industry Experience

Manufacturers with significant backgrounds in your industry can provide tailored solutions and insightful recommendations. Their familiarity with sector-specific demands and obstacles allows them to deliver machines that fully address your operational needs.

Conclusion

In conclusion, selecting the right rubber injection molding machine manufacturers is crucial for achieving consistent, high-quality production across industries. Leading manufacturers like Dekuma, US Molding, and DESMA offer advanced machines, technical expertise, and reliable after-sales support.

When choosing a partner, consider machine specifications, precision, energy efficiency, total cost of ownership, service, automation capabilities, and industry experience. A well-chosen manufacturer ensures optimized performance, reduced downtime, and long-term value for your rubber molding operations.