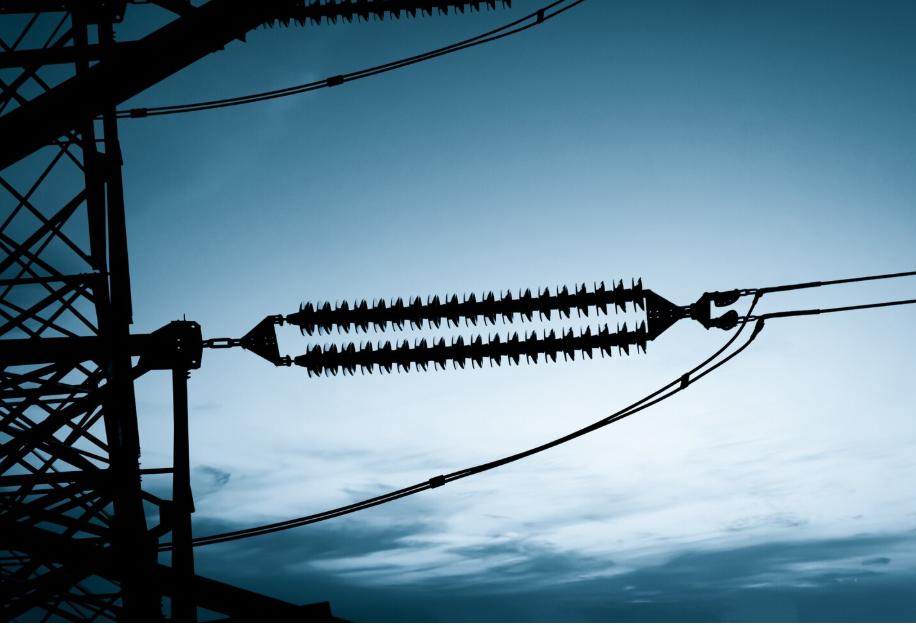

Insulators keep live lines separated from towers, blocking leakage currents and arcs to protect people and equipment. They also support the wires’ weight, while extra creepage distance reduces flashover risk in rain and polluted conditions.

Modern polymer designs, including rubber insulators, shed water and dirt, ensuring safer and more reliable transmission, but producing insulators for different voltage levels still presents unique challenges. In this article, we will explore these difficulties and discuss practical solutions for each voltage range.

Table of Contents

ToggleVoltage Levels and Insulator Requirements

Medium Voltage Insulators

Medium-voltage insulator manufacturing focuses on cost-efficiency and high-volume production, so designs are generally simple. Composite units typically feature an FRP core, a polymer housing, and metal end fittings, with routine tensile and visual checks to ensure quality.

Polymeric types follow IEC 62217 design tests, while rubber insulators require uniform filler distribution and curing to minimise tracking and erosion, helping maintain consistent output at scale.

High Voltage Insulators

High-voltage insulators face greater electrical and environmental stresses, so design margins must be increased. Creepage distance and shed profiles are sized according to IEC 60815-3 to withstand local pollution, while hydrophobic housings help resist wet contamination.

Careful attention to the rod-to-housing bond and seals is essential, as small interface flaws can expand under heat and moisture. Consistent compounding and molding ensure uniform material properties across batches, supporting reliable performance under demanding conditions.

Ultra-High Voltage Insulators

Reliability is paramount for ultra-high voltage insulators. Creepage distances per string are very large, typically 35–54 mm/kV[1], and exceeding 50 mm/kV[2] in severe environments, so parts are long and careful field control is critical.

Rod materials must resist acid attack to prevent brittle fracture, with boron-free glass rods often preferred. Strict lot traceability and 100% routine checks are applied, and standards now cover both AC and high-level DC service for composite long rods.

Maintaining uniform processing across very large molds and fittings ensures consistent performance in demanding applications.

Key Manufacturing Challenges of Rubber Insulators

Material Selection: From Porcelain/Glass to Silicone Composites

The transition from porcelain or glass to silicone composites presents new challenges for insulator manufacturing. Silicone’s hydrophobic properties help reduce contamination by transferring water-repellent characteristics to surface dirt, improving performance in polluted environments. Proper formulation is crucial, with fillers like aluminum trihydrate enhancing tracking, erosion resistance, and fire behavior. The housing must bond well to the FRP rod, and end-fitting seals must remain tight, as a rubber insulator functions reliably only when these interfaces stay dry.

Mechanical & Electrical Reliability over Large Dimensions

Large-span insulators demand careful stress control to prevent structural weaknesses. Poor crimping can initiate cracks or cause slippage, while stress corrosion may lead to brittle fracture. Proper hardware design and grading rings help keep electric fields even, while controlling partial discharge and avoiding voids can ensure consistent dielectric strength. Attention to these details protects both mechanical integrity and flashover margins.

Environmental Resistance: UV, Salt Fog, Icing, Aging

Outdoor insulators face harsh environmental conditions that must be carefully tested. Salt fog performance is verified according to IEC 60507, while UV exposure and weathering cycles require accelerated aging tests per IEC 62217.

Icing conditions demand dedicated freezing and snow tests following IEEE 1783. Although silicone’s hydrophobicity can partially recover after degradation, it does not always do so reliably, making regular monitoring essential.

Quality Consistency: Production, Testing, Certification

Producing rubber insulators at a large scale requires meticulous control to maintain consistent quality. Design verification and material aging are conducted per IEC 62217, while product standards such as IEC 61109 and 61952 guide routine mechanical tests for every lot.

Seal uprightness is carefully checked, and sample audits in certified laboratories help detect any drift. Each rubber insulator lot must be documented with pass/fail records to ensure consistent quality and traceability.

Manufacturing Solutions and Advanced Technologies

Choose Composite Insulators

Composite insulators are lightweight and quick to install, allowing crews to work faster with less lifting equipment. Their silicone housings are hydrophobic, keeping surfaces drier in rain and salt, which enhances pollution performance compared with porcelain or glass.

For these reasons, utilities often favour composite insulators on harsh lines and many UHV routes. Rubber insulators are particularly suitable when weight, installation speed, and pollution resistance are key considerations.

Utilize Rubber Injection Molding Technology

Rubber injection molding forms a one-piece housing that bonds directly to the FRP core, reducing interfaces where moisture or air could create voids or weak bonds. This direct injection method also helps prevent partial discharges during service.

Large hollow units required for UHV applications can be produced using LSR injection molding, enabling precise scaling while ensuring uniform sheds and tight, repeatable dimensions.

Example: How Molding Secures Reliability on HV Projects

Consider a 500–1100 kV line unit. The FRP core and fittings are first prepared, then HTV or LSR is injection-molded around the rod in a closed, degassed tool. Precise control of pressure and curing ensures that the sheath and sheds are uniform, with minimal pores and strong bonding.

Manufacturers verify core-to-housing adhesion and inspect for voids using thermography, followed by partial discharge tests. This process produces durable rubber insulators capable of UHV service, illustrating why composite insulators dominate UHV lines.

Dekuma Rubber Injection Molding Machine for Insulator Production

Rubber insulators for high- and ultra-high-voltage lines demand precise, uniform, and defect-free production. Rubber injection molding provides the technological solution, delivering consistent housing quality and strong core bonding. Achieving this in large-scale or UHV units requires advanced injection molding machines.

With over 25 years of experience and adherence to German manufacturing standards, Dekuma provides rubber injection molding machines specifically engineered to meet these stringent demands.

Depending on the type of insulator being manufactured, Dekuma provides targeted solutions: the RA Series excels in high-voltage applications needing tight dimensional control, whereas the RI Series supports large-scale runs of general insulators with robust reliability.

l RA Series Rubber Injection Molding Machine

The RA Series addresses the challenges of producing high-voltage rubber insulators, including complex shapes, large hollow cores, and strict material uniformity. Its advanced injection and degassing system ensures consistent compound mixing and minimises voids, while precise stroke control guarantees accurate mold filling for long rods.

Energy-efficient thermal insulation reduces heat stress, enhancing reliability during extended production. Designed for silicone rubber and EPDM, this machine delivers stable, high-quality insulators for UHV lines, surge arresters, and other critical applications.

l RI Series Rubber Injection Molding Machine

The RI Series meets the requirements of high-volume rubber insulator production, ensuring uniform quality and minimizing defects. Its three-sided access and direct hydraulic feeding streamline handling of long parts, while dual-seal clamping curbs oil leakage for stable operation.

Precision German hydraulic valves paired with Siemens controls provide consistent, repeatable molding cycles. For even higher throughput, the optional double-station setup allows simultaneous processing, making the RI Series an efficient, dependable choice for manufacturing standard insulators and surge arresters.

Conclusion

Producing rubber insulators across medium, high, and ultra-high voltages presents multiple technical challenges, from material consistency to dimensional precision. Leveraging advanced injection molding technology helps overcome these hurdles, ensuring reliable, high-quality insulators.

Dekuma’s solutions support manufacturers in meeting demanding production standards efficiently at every voltage level. Contact us today to discover how our machines can streamline your insulator production.

References

- Challenges in Insulator Design for UHV. Available at: [https://www.inmr.com/challenges-in-insulator-design-for-uhv/](https://www.inmr.com/challenges-in-insulator-design-for-uhv/). (Accessed on September 17, 2025)

- Challenges in Insulator Design for Overhead Transmission Lines (OHTLs). Available at: [https://education.insulationtg.com/report/uhv-insulator-design-challenges/](https://education.insulationtg.com/report/uhv-insulator-design-challenges/). (Accessed on September 17, 2025)