Compression vs. Injection Molding for Rubber: Key Differences Explained

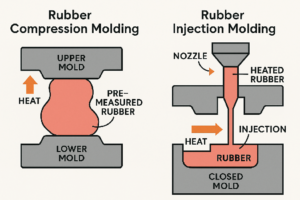

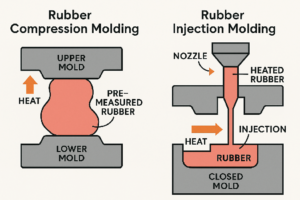

Rubber parts usually start as soft, hot material. In compression molding, you press a pre‑measured chunk between heated dies and let it cure. It’s simple

Rubber parts usually start as soft, hot material. In compression molding, you press a pre‑measured chunk between heated dies and let it cure. It’s simple

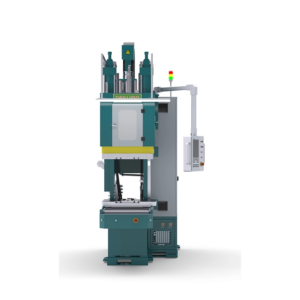

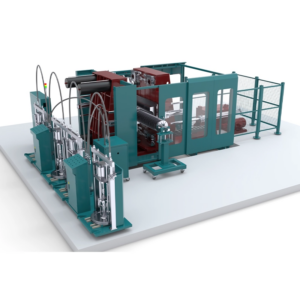

At Dekuma, we understand that investing in high-quality industrial equipment is essential for the success of electrical insulator manufacturing. Our RA Series Rubber Injection Molding

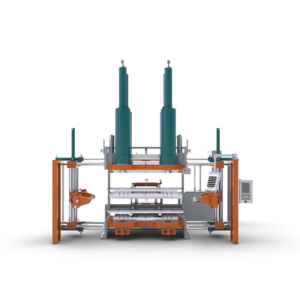

As a prominent factory in China specializing in rubber vulcanizing machine and vulcanized rubber molding machines, we focus on developing cutting-edge rubber vulcanizing equipment designed to

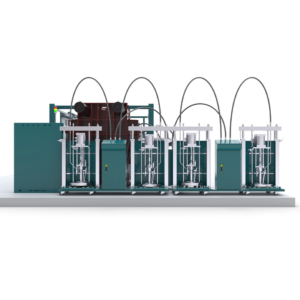

As one of the prominent China rubber injection molding machine suppliers, Dekuma understands the critical importance of sustainability in today’s manufacturing landscape. Our commitment to eco-friendly

At Dekuma, we are committed to delivering innovative solutions for the manufacturing industry, particularly through our innovative liquid silicone rubber injection molding machines. Our commitment to

As a leading player among LSR injection molding machine manufacturers, Dekuma is committed to delivering innovative solutions that enhance both functionality and design in kitchen products.