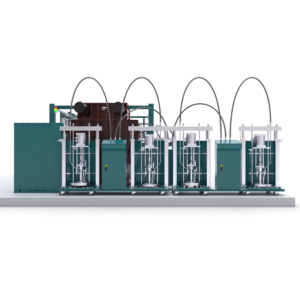

Dekuma’s liquid silicone rubber injection molding machines are engineered to deliver precision and reliability, making them the preferred choice among LSR injection molding machine manufacturers. With our advanced technology, we empower businesses to create safe and effective products for infants, addressing the unique needs of this sensitive market.

Exceptional Safety and Non-Toxicity

One of the primary benefits of using liquid silicone rubber in infant care products is its exceptional safety profile. Our LSR injection molding machine produce items that are non-toxic, hypoallergenic, and free from harmful chemicals. This is critical when it comes to products designed for babies, as parents prioritize safety above all else. By utilizing our liquid silicone rubber injection molding machine, manufacturers can ensure that the end products are compliant with stringent safety regulations.

Silicone rubber is also resistant to bacteria and mold, making it an ideal material for infant care products such as pacifiers, teethers, and feeding accessories. We understand that the well-being of infants is paramount; therefore, we ensure our machines enable the production of safe products that parents can trust.

Versatility in Design and Functionality

Another significant advantage of liquid silicone rubber is its versatility in design and functionality. Our LSR injection molding machines allow for intricate designs and custom shapes that cater to the specific needs of infants. From soft and flexible textures for comfort to durable structures that withstand daily use, our machines provide flexibility in product development.

The ability to create colorful and appealing designs is also essential in the infant care market. Using our machines, manufacturers can produce aesthetically pleasing products that attract both parents and children. This level of customization not only enhances the consumer experience but also helps brands differentiate themselves in a competitive marketplace.

Durability and Longevity of Products

With Dekuma’s liquid silicone rubber injection molding machines, manufacturers benefit from producing durable and long-lasting infant care products. Liquid silicone rubber is known for its resilience under extreme temperatures and its ability to maintain shape and performance over time. This durability is vital for products that may be subjected to rigorous daily use by infants and toddlers.

By investing in LSR injection molding machines, companies can ensure their products have a longer lifespan, reducing waste and contributing to sustainable practices. This not only benefits the environment but also fosters consumer loyalty as parents seek reliable products that can endure the demands of daily life.

Conclusion

In conclusion, the benefits of liquid silicone rubber in infant care products are substantial, particularly when powered by Dekuma‘s advanced LSR injection molding machines. From ensuring safety and non-toxic qualities to providing versatility in design and durability, our machines empower LSR injection molding machine manufacturers to create high-quality, innovative products. As we continue to lead in this industry, we remain committed to delivering solutions that enhance the lives of both manufacturers and consumers alike. Trust Dekuma to support your journey in producing exceptional infant care products that parents can rely on.