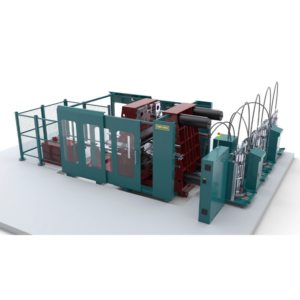

Advanced control systems that have been integrated with durable machinery are frequently responsible for the precision that is achieved in manufacturing. In operations that call for a high degree of accuracy, such as liquid silicone rubber molding, Dekuma places a strong emphasis on this integration. Our methodology includes the construction of equipment that is able to manage the complexity of Liquid Silicone Rubber (LSR), which is essential for guaranteeing that crucial components used in the healthcare, automotive, and consumer electronics industries are produced with consistent output. In this article, the function that intelligent systems play in a contemporary LSR injection molding machine is taken into consideration.

Intelligent Control for Consistent Output

A central component of our liquid silicone rubber LSR injection molding machine is its operational intelligence. The system runs on an S98 smart B&R control platform, which is integrated with top-tier electrical components. This combination functions to lower the possibility of operational faults and maintain a consistent production rhythm. The reliability of this system is a reason many regard us as a capable LSR injection molding machine supplier, as it reduces unexpected interruptions and supports sustained manufacturing cycles.

Simplifying Complex Operational Procedures

The interface for this LSR injection molding machine includes a 10.4-inch color touchscreen. This display provides a clear and straightforward point of interaction for the operator. The design of the interface makes monitoring and adjusting process parameters more manageable, which contributes to smoother daily operations. This focus on usability helps reduce the learning curve for new personnel and allows experienced operators to execute their tasks with improved command over the liquid silicone rubber LSR injection molding process.

Addressing the Needs of Specialized LSR Applications

The value of a sophisticated control system becomes apparent in subdivided, high-precision fields. For manufacturers producing medical devices or intricate silicone seals, the margin for error is minimal. The smart control system in this machine aids in maintaining the strict parameters required for such applications. It offers the dependability needed for complex production schedules where consistency and accuracy are paramount, making it a practical asset for specialized manufacturers.

We build our liquid silicone rubber LSR injection molding machines to offer reliability and operational clarity. The inclusion of a smart control system and an intuitive interface reflects our commitment to functional design. For businesses involved in precision LSR molding, this equipment provides a structured approach to managing a demanding material, supporting efforts to maintain quality in specialized production environments.