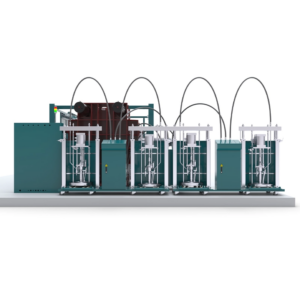

Dekuma is aware of how important energy efficiency is to enterprises in the cutthroat market of today. Manufacturers are searching for methods to reduce energy use without sacrificing performance due to growing environmental restrictions and rising energy expenses. Our rubber injection molding machine is therefore made especially to provide excellent performance while consuming a lot less energy. Dekuma’s machines, such as the RA, RT, and RI Series, offer an economical and ecologically responsible solution for rubber molding operations by integrating cutting-edge technologies including servo-driven technology and double-layer thermal insulation.

Energy-Saving Thermal Insulation Technology

One of the standout features of Dekuma’s rubber injection molding equipment is its imported double-layer thermal insulation plates. These high-performance plates are engineered to significantly reduce energy consumption by up to 40%. The improved insulation ensures that heat is retained more effectively during the molding process, reducing the need for excess energy to maintain optimal operating temperatures. This energy-saving technology helps manufacturers lower their operational costs while also reducing their environmental footprint. As a result, manufacturers can achieve cost-efficient production without sacrificing quality, making it a sustainable choice for modern manufacturers who are looking to align their operations with green practices.

Advanced Servo-Driven Systems

Another key feature that sets Dekuma’s machines apart is the servo-driven technology. For example, the RT Series rubber injection molding machine uses a servo-driven system that adjusts energy consumption based on the specific pressure and flow requirements of each mold cycle. This means that the machine only consumes the exact amount of energy needed, eliminating unnecessary power usage and significantly reducing electricity costs. Unlike traditional molding machines that operate at a constant energy output regardless of the actual requirements, the servo-driven system provides a much more efficient and intelligent energy usage model, further enhancing cost savings.

Reduced Operational Costs with Reliable Performance

With these energy-efficient designs and advanced systems, Dekuma’s rubber injection moulding machines help manufacturers cut down on energy costs while maintaining consistent, reliable performance. Our machines are designed not only to reduce operating expenses but also to ensure that production quality is never compromised. This makes them ideal for businesses that want to maximize their return on investment while minimizing their environmental impact. Whether you’re operating in the automotive, industrial, or consumer goods sectors, these machines offer a proven solution to achieve cost savings and higher productivity.

Conclusion

Durability and performance are well balanced in Dekuma‘s energy-efficient rubber injection molding equipment. Our machines offer a complete solution to lower energy consumption and operating costs by integrating technologies like servo-driven systems and energy-saving thermal insulation. Dekuma’s machines are the best option for your rubber molding operations if you’re searching for high-performance machinery that can increase your profitability and aid the environment.