When versatility defines production success, Dekuma stands ready. As a leading force in advanced manufacturing solutions, Dekuma supplies a comprehensive range of rubber injection molding machine systems – from vertical, horizontal, and C-frame configurations to highly specialized niche applications like rubber track molding and glass encapsulation. This isn’t just equipment; it’s engineered potential, transforming raw materials into precision components for automotive, construction, energy, and defense industries globally. Choosing Dekuma means accessing the right rubber molding equipment precisely configured for unique operational demands, backed by decades of engineering excellence under our parent company, Cosmos Machinery Enterprises Limited.

The Foundation: Versatile Rubber Molding Equipment for Core Applications

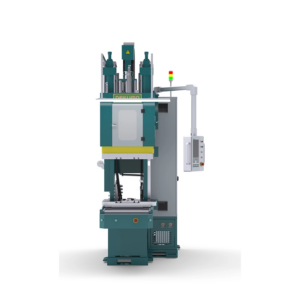

Dekuma’s core strength lies in offering adaptable, high-performance rubber molding equipment designed for reliability. Vertical machines excel in intricate, multi-cavity molds requiring precise insert placement, ideal for complex automotive seals or electrical components. Horizontal configurations deliver power and stability for larger, high-volume parts like construction vehicle mounts or agricultural fittings. C-frame presses provide exceptional accessibility for manual loading/unloading or quick mold changes in smaller batch production. Every Dekuma rubber injection molding machine integrates robust construction, energy-efficient hydraulics, and intelligent control systems. This ensures consistent, repeatable quality, reduced cycle times, and minimized waste – fundamental advantages for manufacturers seeking scalable efficiency. Investing in Dekuma rubber molding equipment translates directly into enhanced productivity and component integrity, meeting the strictest industry standards.

Beyond Standard: Specialized Rubber Molding Machine Solutions

True innovation addresses unique challenges. Beyond standard presses, Dekuma pioneers specialized rubber molding machine technology for cutting-edge applications. Our rubber track molding systems are engineered for the demanding off-road and agricultural sectors, producing durable, seamless tracks with exceptional wear resistance and traction. Similarly, Dekuma’s glass encapsulation systems represent precision engineering at its finest, seamlessly bonding rubber seals directly onto automotive or architectural glass with flawless accuracy and adhesion. These niche solutions showcase Dekuma’s commitment to pushing boundaries. They aren’t modifications; they are purpose-built rubber injection molding machine platforms developed through deep application understanding. For manufacturers requiring solutions beyond conventional capabilities – whether producing massive industrial tracks or delicate encapsulated glass components – Dekuma provides the specialized rubber molding equipment and technical expertise to turn complex visions into reliable, high-volume production realities.

Conclusion

Dekuma’s identity is built on delivering the precise rubber injection molding machine technology needed, whether it’s versatile vertical, horizontal, or C-frame presses for core manufacturing or groundbreaking specialized systems for rubber tracks and glass encapsulation. Our extensive range of rubber molding equipment ensures there’s an optimal solution for every application complexity and volume requirement. Partnering with Dekuma means more than acquiring machinery; it’s gaining access to engineering depth, application-specific expertise, and unwavering support designed to maximize operational efficiency and product quality. For manufacturers aiming to lead, innovate, and excel, Dekuma provides the robust, adaptable, and specialized rubber molding machine foundation essential for global competitiveness. Your solution awaits.