In the modern manufacturing landscape, industries across agriculture, construction, and defence require high-quality machinery to produce durable rubber tracks that meet specific operational needs. Rubber track molding machines and rubber track making machines are essential tools in this process. As companies look for precision, efficiency, and sustainability, Dekuma continues to lead the way with advanced technologies that ensure superior production outcomes.

Transforming Industries with Rubber Track Molding Machines

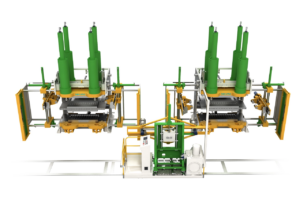

The role of rubber track molding machines cannot be overstated when it comes to producing rubber tracks that withstand harsh conditions. Molding technology is key in ensuring the strength, durability, and performance of rubber tracks, which are crucial for vehicles and machinery in agriculture, construction, and military sectors. Dekuma’s advanced rubber track building machines provide precise molding capabilities that ensure every track meets the high standards required for heavy-duty applications.

The rubber track molding machine offered by Dekuma integrates state-of-the-art technology to optimize the curing and shaping process, resulting in tracks that perform under extreme conditions. These machines ensure uniform quality and consistency, enhancing overall product reliability. Whether it’s providing excellent traction on agricultural machinery or ensuring safety on construction vehicles, our molding systems are designed to meet demanding industry requirements.

Efficiency at Scale with Rubber Track Making Machines

Efficiency is a top priority in manufacturing processes, and Dekuma’s rubber track making machines are engineered to meet high production standards without compromising quality. Automation is central to these machines, increasing production speed while maintaining the precision needed for every batch of rubber tracks.

With energy-efficient designs, Dekuma’s rubber track building machines help businesses reduce their environmental impact and improve their operational costs. The integration of automated processes ensures consistent output, limiting errors and reducing downtime. This helps companies scale their operations while maintaining cost-efficiency, offering long-term savings and increasing productivity. Whether in construction or defence applications, these machines are designed to optimize every aspect of rubber track production, supporting businesses in meeting their production targets while lowering overall costs.

Dekuma’s Commitment to Global Partners

Dekuma’s approach to business is rooted in strong partnerships, supporting industries like agriculture, construction, and defence. Through collaboration, we ensure that each rubber track molding machine and rubber track building machine is tailored to meet the specific needs of clients. Their commitment to client-centered innovation ensures that their machinery meets global standards and adapts to changing industry demands.

With Dekuma’s advanced technologies, companies in diverse sectors benefit from solutions that enhance production efficiency and performance. By staying ahead of industry trends and continually improving their machinery, we are committed to helping businesses succeed and grow in an ever-evolving marketplace. Their forward-thinking approach also ensures that clients are well-prepared for future challenges in rubber track production.

Conclusion

Our rubber track molding machines and rubber track making machines represent the pinnacle of innovation in the industry. As a trusted partner for businesses worldwide, Dekuma continues to deliver superior machinery that drives efficiency, sustainability, and long-term value.