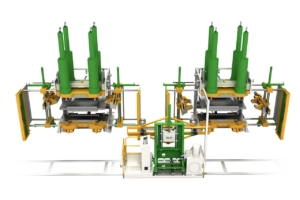

How Rubber Track Machines Operate: An Inside Look at Their Functionality

At Dekuma, we understand the crucial role that rubber track machines play in ensuring durability, efficiency, and precision in the production of rubber tracks. These machines are essential in various industries, from agriculture to electric and defense, providing vehicles and machinery with the traction and strength they need to operate in tough environments. But how do […]

What to Know About the Machines Used for Automotive Injection Molding

In the world of automotive manufacturing, precision is key. That’s why automotive injection molding has become an essential process for creating components with exacting specifications. But what kind of machines are used to achieve this? As a automotive injection molding company, we specialize in high-performance machinery designed to produce automotive parts with the highest standards of […]

How to Choose the Right Rubber Molding for Your Car: A Guide from Dekuma

When it comes to automotive manufacturing, selecting the right rubber molding for cars is a crucial step in ensuring durability and performance. Dekuma, a well-regarded automotive injection molding company, offers a wide range of solutions for various vehicle models. With their extensive experience in rubber molding for cars, understanding how to pick the best product can […]

The Evolution of Rubber Mouldings in Automotive Industry

The automotive sector has seen a dramatic transformation over the years, with advancements in manufacturing processes significantly improving vehicle safety, durability, and overall performance. One such innovation has been in the production of rubber mouldings for cars. These components play a crucial role in sealing, insulation, and even noise reduction in vehicles. Over time, the […]

Understanding Automotive Rubber Mouldings Standards: Key Insights

Automotive rubber mouldings are crucial components in the manufacturing of vehicles, providing essential sealing and insulation solutions. The process of molding these components requires precision and consistency, and as an automotive injection molding company, Dekuma offers high-quality solutions to meet these demanding standards. Understanding the key factors that govern the production of these rubber parts […]

EPDM vs. FKM: Choosing the Right Material for Automotive Fluid Seals

When designing sealing components for automotive fluid systems, the material choice can be a game-changer in terms of performance and longevity. As an automotive injection molding company, we at Dekuma specialize in delivering high-quality sealing solutions tailored to the specific needs of the automotive industry. Two of the most commonly used materials for these applications […]

Why Certifications Are Essential When Choosing an Automotive Injection Molding Company

In the automotive industry, selecting the right automotive injection molding company is crucial for ensuring the highest quality and efficiency of your production processes. The need for precision, reliability, and advanced technologies cannot be overstated. Dekuma, a trusted name in the industry, emphasizes the importance of certifications when it comes to choosing the right partner for […]

Rubber Injection Molding vs. Transfer Molding: Understanding the Differences in Quality

When it comes to manufacturing rubber products, choosing the right molding technique can make a significant difference in the quality and efficiency of the final product. At Dekuma, we provide both rubber injection molding machines and injection rubber moulding machines, but how do these processes compare, and which one is the best for your production needs? […]

Debunking Common Misconceptions About Rubber Injection Molding Machines

At Dekuma, we are constantly working to improve the way industries approach rubber product manufacturing. There’s often a lot of confusion around rubber injection molding machines, especially when it comes to their functionality, cost, and precision. Many people think that to get a machine that provides high precision, you’ll need to make major compromises on […]

How to Know When It’s Time to Upgrade Your Rubber Moulding Machine

When it comes to maintaining your rubber injection molding operation, having the right equipment is key. Over time, even the best machines can show signs of wear and may struggle to keep up with evolving demands. At Dekuma, we specialize in providing high-quality rubber injection molding machines and rubber moulding machines, ensuring that you’re always one […]