Glass Molding Equipment vs. Other Methods: A Detailed Comparison

When it comes to producing high-quality glass encapsulations for the automotive industry, choosing the right glass injection molding machine or glass molding equipment can significantly impact the final product’s performance and manufacturing efficiency. In this article, we will dive into how Dekuma’s glass molding solutions stack up against alternative methods, providing an in-depth look at each […]

How to Maximize the Longevity of Your Glass Molding Machine Molds

Maintaining the molds of a glass molding machine is essential for ensuring long-term productivity and reducing the risk of downtime. At Dekuma, we understand how critical mold longevity is for companies working with glass encapsulation, particularly in industries like automotive manufacturing. Below are key practices for maintaining the molds of your glass molding machine to ensure […]

Advantages of Using a Liquid Silicone Rubber (LSR) Injection Molding Machine

Liquid Silicone Rubber (LSR) is increasingly used in a range of industries due to its exceptional durability, flexibility, and safety. If you’re considering adding LSR injection molding machines to your production line, it’s essential to understand their various advantages. Dekuma provides a versatile and efficient solution for those looking to enhance their production capacity while ensuring […]

Why Dekuma is the Right Choice for Your LSR Injection Molding Needs

When it comes to finding a reliable partner for your LSR injection molding machine needs, choosing the right manufacturer is critical. The right equipment can ensure efficiency, precision, and versatility in producing high-quality silicone parts. As a company that specializes in this field, Dekuma has been at the forefront of providing advanced and effective solutions […]

Understanding the LSR Molding Process: How Does It Work?

Liquid Silicone Rubber (LSR) molding has become an essential manufacturing process, especially for industries requiring precision, flexibility, and safety in their components. Whether it’s for baby care products, food containers, or electronic components, the LSR injection molding machine is a game-changer. But what does the process involve, and how do machines like the Dekuma LSR molding […]

What Exactly is LSR Injection Molding?

At Dekuma, we understand that liquid silicone rubber (LSR) is an essential material for many industries. The LSR injection molding machine plays a crucial role in shaping this versatile material into usable, high-quality components. But what makes this process so special? Let’s explore the details behind LSR injection molding machines and why they are a game […]

The Versatility of LSR Injection Molding Machines in Modern Industries

At Dekuma, we understand the importance of flexible manufacturing in the modern world. That’s why we’ve invested heavily in the development of the LSR injection molding machine, which offers exceptional versatility for a range of industries. With advancements in liquid silicone rubber (LSR) technology, Dekuma is providing manufacturers with efficient, reliable, and precise solutions that […]

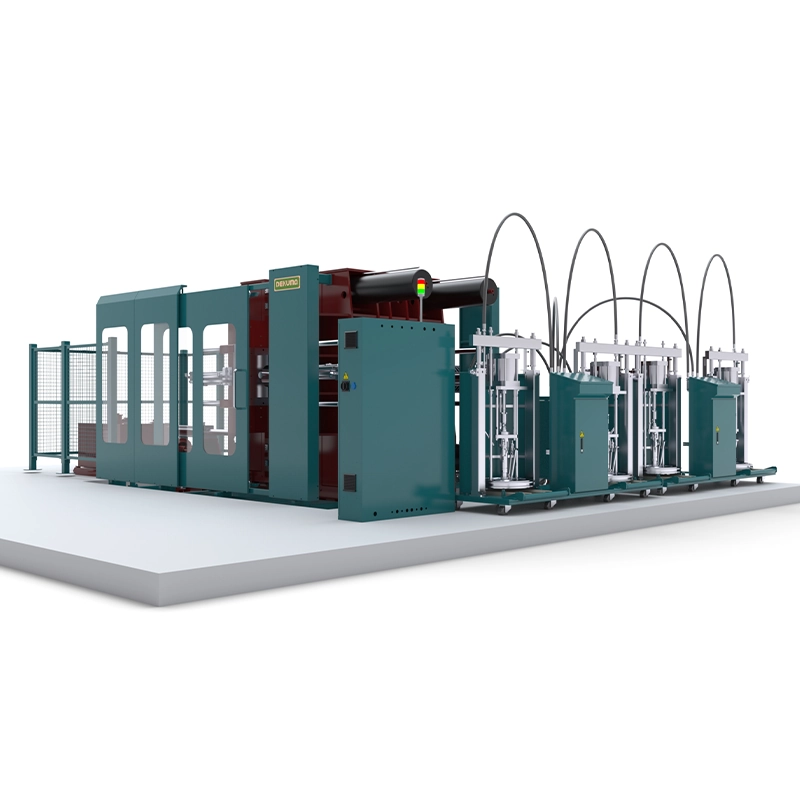

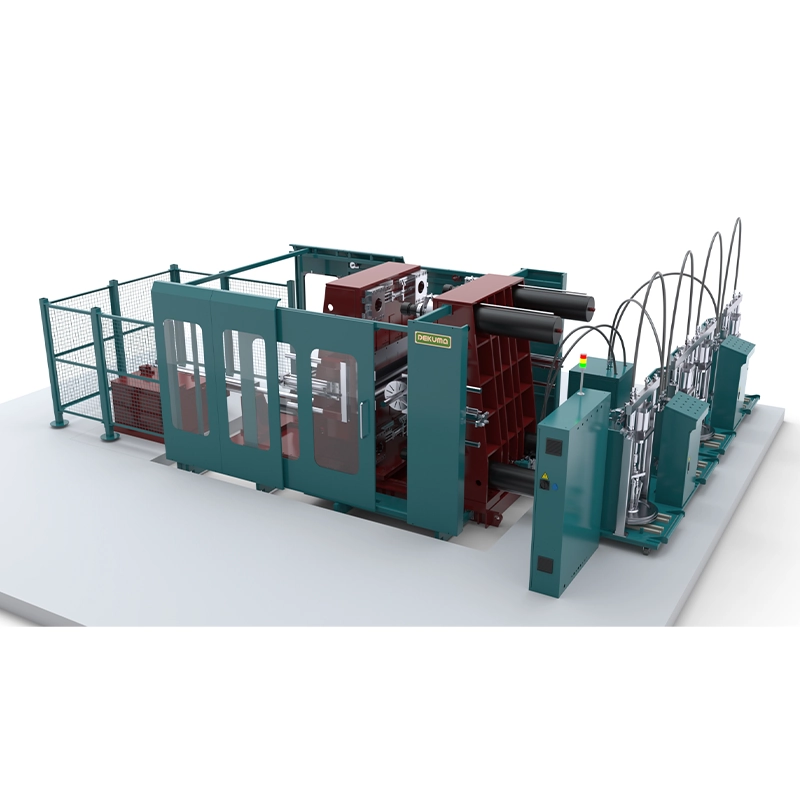

What Makes a Horizontal Injection Molding Machine Essential for Precision Manufacturing?

In the world of manufacturing, the horizontal molding machine plays a crucial role in creating precision rubber parts such as sealing rings. This type of machine offers remarkable efficiency and reliability, especially when used for processing materials like natural rubber, nitrile rubber, or fluoro rubber. At Dekuma, we have designed our injection molding machine horizontal to […]

Is Injection Molding Considered a CNC Process?

Injection molding is a widely used manufacturing process, but is it classified as a CNC (Computer Numerical Control) machine process? The confusion may arise due to the similarities in automation and precision found in both CNC machining and injection molding. However, while both processes involve precise control of machines, they operate on different principles and […]

Horizontal vs. Vertical Injection Molding Machines: Key Differences Explained

When it comes to selecting the right molding machine for manufacturing plastic products, the choice between horizontal injection molding machines and vertical ones is crucial. Both types have distinct advantages and are suitable for different applications. At Dekuma, we provide a range of horizontal injection molding machines tailored for high-precision manufacturing, but understanding how they differ […]