- Yinzhu Road, Zhouwu Industrial Park, Dongcheng District, Dongguan City, Guangdong Province, China.

- Email:info-rim@dekuma.com

- Tel: +86-769-22667207

- Mobile: +86-15622909600

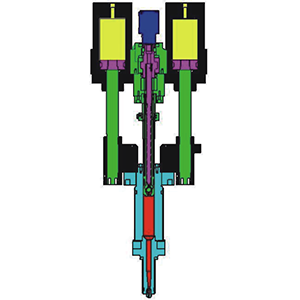

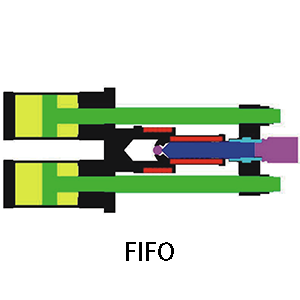

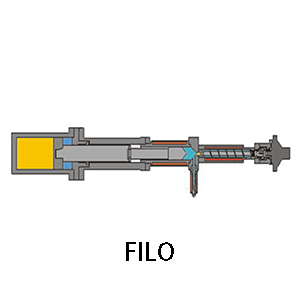

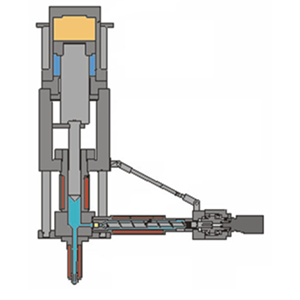

▪ Entire plasticization and injection system optimized by German technical consultants.

▪ Screw slows down before plasticizing is complete; easy-to-disassemble injection piston.

▪ Three separate injection zones with adjustable pressure and speed, Three separate dwell zones with adjustable pressure and speed.

▪ Finite element stress analysis is utilized when designing all key parts to ensure adequate rigidity of the parts.

▪ Three separate clamping zones with adjustable pressure and speed.

▪ Adjustable low pressure and high pressure protection settings.

▪ Multiple venting cycle settings, with precise clamping stroke control.

▪ Controlled by a specialized industrial computer with dedicated software, with all electrical components sourced from internationally renowned brands.

▪ Equipped with original German-made proportional flow valves, pressure control valves, and directional valves, ensuring smooth machine operation with no leakage, no malfunction, significant endurance, and an extended service life.

▪ Separate heat transfer oil system for plasticizing and injection barrel enables indipendent temperature regulation and ensures precise temperature control.

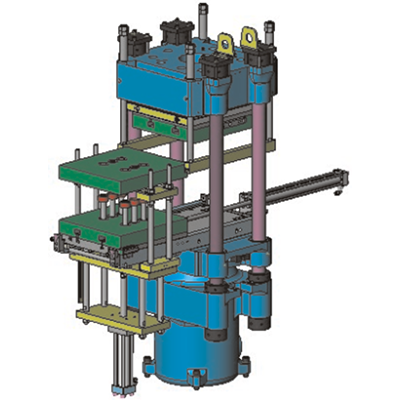

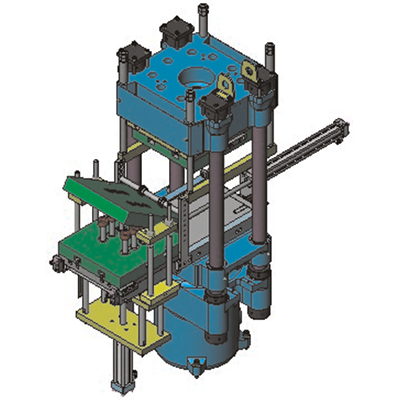

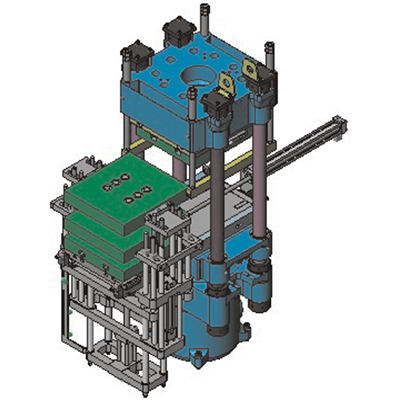

The machine adopts a modular design. Various options can be selected to meet each customer’s different product and process requirements, guaranteeing maximum production efficiency.

Device name | RV | RA | RC | RI |

Upper Mechanical Mould Lifting Device | ● | ● | ● | ● |

Upper Hydraulic Mould Lifting Device | ● | ● | ● | ● |

Lower Mechanical Mould Holding Device | ● | ● | ● | ● |

Lower Hydraulic Mould Supporting Device | ● | ● | ● | ● |

Mid Mould Sliding Device | ● | ● |

| ● |

Lower Mould Sliding Device | ● | ● | ● | ● |

Single-layer Ejecting Device | ● | ● | ● | ● |

Double-layer Ejecting Device | ● | ● |

| ● |

Single-layer Upper Ejecting Device | ● | ● | ● | ● |

Mould Tick-rack Device | ● | ● |

| ● |

Silicon Rubber Feeding Device | ● | ● | ● |

|

Cold Runner Device | ● | ● | ● |

|

Cold Runner With Heat Transfer Oil Device | ● | ● | ● |

|

All Round Cover | ● | ● | ● |

|

Vaccum Pump | ● | ● | ● | ● |

CE Safety Standards | ● | ● | ● | ● |

Either non-standard or specially designed rubber injection moulding machines can be provided per customer’s article requirements.

Why Choose Dekuma:

Dekuma has a complete team of experts that can meet the needs of different customers.

Raw materials are meticulously selected and processed, guaranteeing reliability and stability of custom rubber machines.

We build machines designed specifically for your application, ensuring optimal performance. See Industries We Serve.

We foster long-term relationships with satisfied clients globally, including leading equipment suppliers. See Case Studies.

Ready To Discuss Your Custom Rubber Machine Project? Let’s Talk. We are looking forward to creating the greatest value for you.