- Yinzhu Road, Zhouwu Industrial Park, Dongcheng District, Dongguan City, Guangdong Province, China.

- Email:info-rim@dekuma.com

- Tel: +86-769-22667207

- Mobile: +86-15622909600

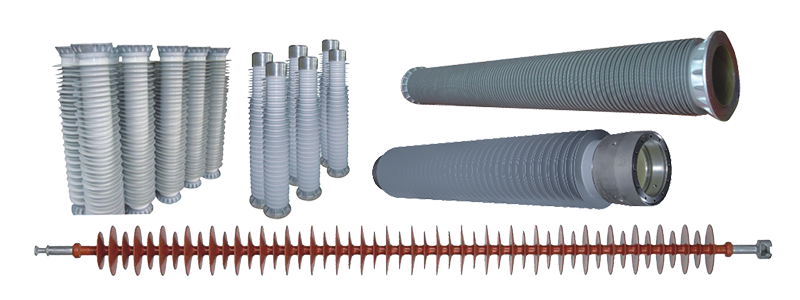

Can process HTV silicone rubber to produce long-rod insulators, hollow core bushings, arresters, cable accessories and switchgear.

Main features include:

HTV Silicone Applications

Capable of processing HTV silicone rubber to produce long-rod insulators, hollow core bushings, arresters, cable accessories, and switchgear. Being a dedicated solid silicone injection molding machine, it offers reliable performance for large-format solid silicone rubber molding in high-voltage insulation applications.

Top-Opening Mold Structure

Top-opening mold structure significantly reduces operating height, making operation more convenient and comfortable.

Stable Clamping Design

With a block-type structure, the clamping unit keeps the mold weight centered, which makes the machine more stable during operation. When the mold opens to its limit, the block auto-locks to protect mechanical, hydraulic, and electrical components—an essential safeguard for any solid rubber injection molding machine.

Quick Mould Adjustment

This machine adopts hydraulic blocks to adjust mold height during mold changes, making the process easier, faster, more accurate, and more efficient. This function is particularly valuable in solid silicone rubber injection molding workflows that demand frequent changeovers with minimal downtime.

Optimized Injection System

This solid silicone molding machine features optimized plasticization and injection systems to improve screw feeding, mix materials more evenly (better homogenization), and release trapped air more effectively (enhanced venting).

Advanced Control System

Dekuma’s solid silicone rubber molding machine is equipped with an Austrian B&R control system and a 10.4″ TFT color touch screen, making operation more intuitive and user-friendly.

DOWNLOAD DEKUMA rubber injection molding machine brochure (English).

Suitable for producing long-rod insulators, hollow core bushings, arresters, cable accessories and switch gear using HTV silicone rubber.

Send us your business requirements, and we’ll get back to you within 24 hours.

Technical specifications for the solid silicone injection molding machine are as follows:

| ITEM | Unit | RIMM for Rod Insulator | RIMM for Hollow Core Insulator | ||

| RT560 | RT1100A | RT1200B | RT1500 | ||

| Injection Pressure | bar | 1200 | 1200 | 1200 | 1200 |

| Injection Volume | cc | 13000 | 25000 | 40000 | 40000/50000 |

| Screw Dia. | mm | 65 | 90 | 90 | 90 |

| Clamping Force | kN | 5600 | 11000 | 12000 | 15000 |

| Mould Opening Stroke | mm | 700 | 800 | 1600 | 700 |

| Distance Between Heating Plates | mm | 940 | 1080 | 2200 | 1050 |

| Min.Mould Thickness | mm | 280 | 280 | 600 | 350 |

| Heating Plate Dimension | mm | 1600 x 630 | 2700 x 800 | 2000 x 1500 | 3600 x 830 |

| System Pressure | bar | 210 | 210 | 210 | 210 |

| Machine Weight | Ton | 20 | 49 | 70 | 72 |

| Machine Dim.(L x W x H) | m | 5.65 x 3 x 3.8 | 6.9 x 4.3 x 3.9 | 11.8 x 6.3 x 7.4 | 8.9 x 7.6 x 4.6 |

| Hydraulic Pump Motor Power | kW | 22 | 37+ 4 | 37+ 4 | 37+ 4 |

| Heating Plate Power | kW | 36 | 90 | 120 | 133 |

| Total Power | kW | 68 | 146 | 176 | 210 |

We reserve the right to change any design and specification without notice.

As a leading hydraulic injection molding machines manufacturer, we proudly introduce the RV-Se Series—a high-performance solution powered by a precision servo system.

Designed for demanding applications in the automotive industry, these machines are engineered to process TPV, TPE, flexible modified PVC, and other raw materials manufactured by injection molding.

Our RV-Se hydraulic rubber molding machines offer clamping forces from 500 to 1,000 tons, making them ideal for large-scale production. Known for reliability and performance, these machines embody our commitment to cutting-edge R&D and strict quality control.

Key features of our hydraulic molding machines include:

These hydraulic rubber machines feature a modular design, offering the flexibility of customization to suit your specific molding requirements.

DKM-RC series C-frame rubber injection molding machines are used for precision rubber parts, sealing strip joints, seals, skeleton oil seals, and TPU products.

Main features of this C frame press machine include:

Suitable for general insulators and rubber products.

Suitable For 9-22 Inch Solid Tyres

Main Features Include:

Contact us for tailored solutions to meet your rubber injection needs and drive your success.

+86-769-22667207

+86-15622909600