Vulcanization has been a cornerstone in the rubber industry for centuries, enhancing the durability and flexibility of rubber products. Today, even in the age of advanced manufacturing technologies, vulcanization is still widely used, particularly in the production of high-performance rubber tracks. At Dekuma, we provide cutting-edge rubber vulcanizing machines designed to meet the needs of industries like agriculture, construction, and even military applications. But is this time-honored process still relevant in modern times? Let’s take a closer look.

The Importance of Rubber Vulcanization in Manufacturing

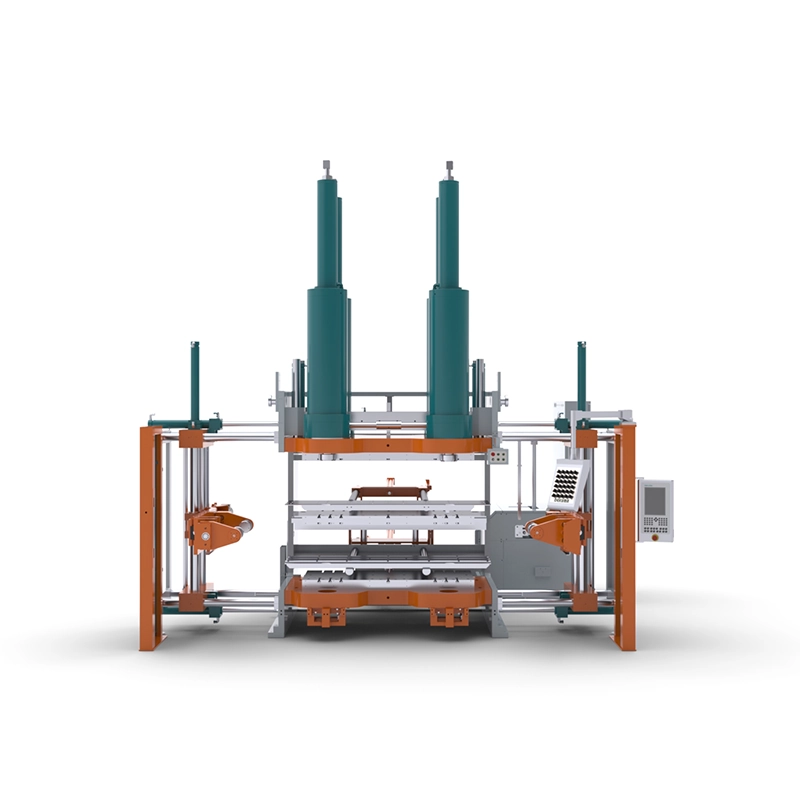

The rubber vulcanization machine plays a vital role in ensuring that rubber products possess the right balance of elasticity, strength, and resistance to wear and tear. By applying heat and pressure, this process transforms raw rubber into a more durable material that is critical for demanding applications. Our Dekuma machines are specifically engineered to enhance this transformation, offering automated processes that increase efficiency and reduce manual labor. With advanced control systems and precision engineering, Dekuma rubber vulcanization machines also ensure consistent quality and improved production output, meeting the high standards required by industries such as automotive and manufacturing.

How Dekuma’s Rubber Vulcanizing Machines Are Revolutionizing the Industry

At Dekuma, we’ve integrated high levels of automation into our rubber vulcanization machines, cutting down labor requirements by up to 50%. Our machines utilize advanced features like automatic rubber loading and demolding, which ensure smooth and consistent production cycles. This innovation is key for manufacturers looking to increase throughput without compromising on product quality. Our vulcanizing machines also incorporate smart monitoring systems, ensuring that all critical parameters, such as temperature, pressure, and clamping force, are precisely controlled.

Continuous Improvement for Enhanced Performance

One of the hallmarks of Dekuma’s rubber vulcanization machines is their ability to adapt and evolve. We constantly iterate and refine our machines to deliver better performance and simpler maintenance. Our continuous improvements focus on core vulcanizing technologies, ensuring that our customers benefit from the latest advancements in rubber production. This ongoing enhancement makes Dekuma a reliable partner for businesses seeking high-quality, energy-efficient, and easy-to-maintain vulcanization solutions.

Conclusion

The process of vulcanization remains essential in the production of durable rubber products, particularly in the manufacturing of rubber tracks for agriculture, construction, military, and snowmobile tracks. At Dekuma, our innovative rubber vulcanizing machines ensure that this vital process is more efficient and cost-effective than ever before. By incorporating automation, smart monitoring, and continuous refinement, we help businesses achieve higher productivity and superior product quality.