Vulcanization has revolutionized the rubber industry, transforming raw rubber into a material that is much stronger, more durable, and versatile. At Dekuma, we understand the process and the machinery that make this possible. In this article, we will explore the key differences between vulcanized rubber and raw rubber, and why the Dekuma rubber vulcanizing machine plays a crucial role in enhancing rubber quality and performance.

The Process of Vulcanization: A Game Changer

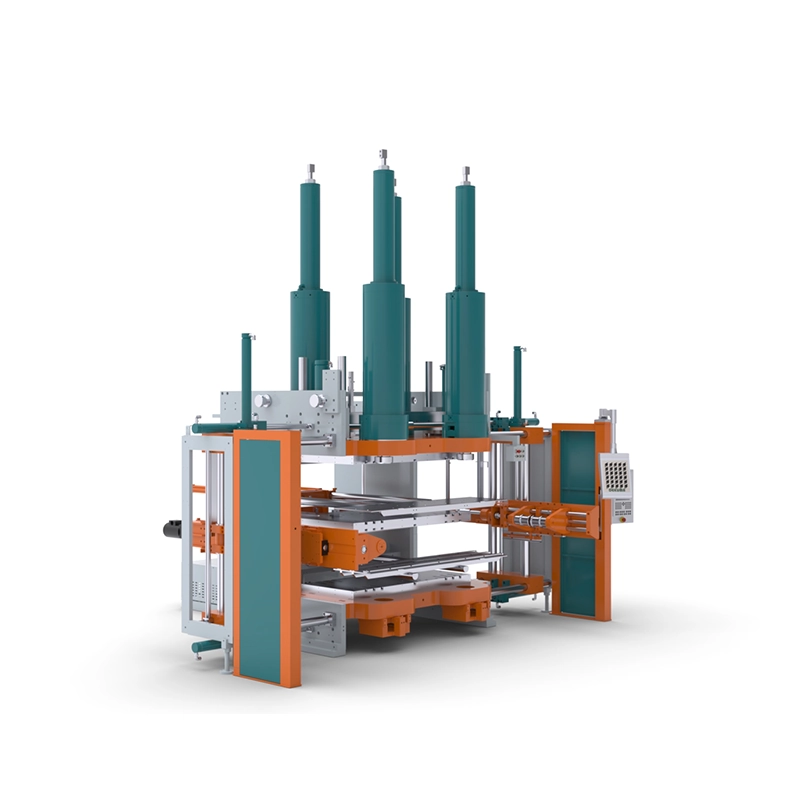

Vulcanization involves heating raw rubber with sulfur, creating cross-links between the polymer chains. This chemical process improves the strength and elasticity of the material, making it far more resistant to wear and tear. The Dekuma rubber vulcanizing machine plays a pivotal role in this process by applying precise pressure and temperature control to ensure a perfect vulcanization cycle. Unlike raw rubber, vulcanized rubber can withstand extreme environmental conditions, from high heat to cold temperatures, making it ideal for use in demanding applications like agriculture tracks and snowmobile tracks.

The Benefits of Vulcanized Rubber Over Raw Rubber

Raw rubber, while flexible, lacks the durability needed for high-stress applications. The vulcanization process strengthens the rubber by enhancing its resistance to abrasion, oils, and extreme temperatures. This is particularly evident when using a rubber vulcanizer machine like those from Dekuma, which guarantees a consistent, high-quality output. Vulcanized rubber also offers superior load-bearing capabilities, which are crucial for heavy-duty applications such as construction tracks and military tracks. These features ensure that vulcanized rubber provides a much longer service life compared to raw rubber.

Dekuma’s Innovation in Rubber Vulcanization

At Dekuma, we prioritize innovation in every step of the production process. Our rubber vulcanizing machines are designed with advanced features like intelligent curing shutdown, smart monitoring systems, and continuous iteration. These technologies allow us to produce vulcanized rubber with superior performance, reducing energy consumption and increasing productivity. By leveraging our Dekuma rubber vulcanizing machine, manufacturers can achieve better quality tracks that require less maintenance and have a longer lifespan. The result is a cost-effective solution that does not compromise on quality or efficiency.

Applications of Vulcanized Rubber in Various Industries

The versatility of vulcanized rubber makes it indispensable in many industries. The robust nature of vulcanized rubber makes it the ideal choice for agricultural, construction, and military tracks. With the precise control offered by Dekuma’s machines, vulcanized rubber can be manufactured to meet the specific needs of different applications. Whether it’s the rugged conditions of military operations or the heavy loads on construction sites, vulcanized rubber delivers the durability and strength required for optimal performance.

Conclusion

Vulcanized rubber offers undeniable advantages over raw rubber, and at Dekuma, we ensure that the vulcanization process delivers the highest quality rubber tracks. Our rubber vulcanizing machines provide automatic feeding, precise control, and energy-efficient operation, making them the perfect choice for manufacturers looking to enhance their rubber production. By investing in Dekuma’s rubber vulcanizer machine, you can be confident that your products will stand the test of time in any application, from military tracks to snowmobile tracks.