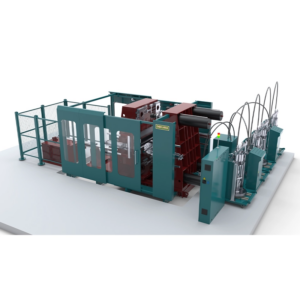

Dekuma’s Liquid Silicone Rubber (LSR) injection molding machines have established themselves as the industry standard, thanks to their innovative features and robust performance. Known for precision, consistency, and adaptability, Dekuma’s LSR injection molding machines are a key player in industries ranging from electronics to food-grade applications. Here’s why we continue to lead the market.

High-Tech Features for Consistency and Quality

Dekuma’s LSR injection molding machine is built with cutting-edge technology designed to deliver top-tier consistency and quality. One of the standout features is its patented synchronized dosing system, which ensures that liquid silicone rubber is dispensed accurately and efficiently for every cycle. This system eliminates variability and minimizes material wastage, ensuring a high level of precision in every batch produced.

A key component that contributes to the machine’s high-precision performance is the static mixer. The mixer guarantees thorough and uniform blending of the silicone rubber before it enters the mold, helping achieve superior results with every injection. Whether you are producing medical parts, automotive seals, or consumer goods, our liquid silicone rubber injection molding machine ensures that quality remains consistent throughout production.

Increased Efficiency with Smart Control Systems

Dekuma’s LSR injection molding machines are equipped with the S98 Smart B&R Control System, a cutting-edge control system designed to optimize operational efficiency. The system offers real-time monitoring of all key parameters, allowing manufacturers to make adjustments quickly and effectively.

Operators will appreciate the intuitive interface of the 10.4-inch color touchscreen, which simplifies the operation of the machine. With easy navigation, the touchscreen allows operators to set production parameters, monitor cycles, and troubleshoot potential issues without requiring advanced technical expertise. This smart control system reduces the chances of human error, increases machine uptime, and enhances overall production efficiency.

Meeting Industry Demands with Versatile Applications

Dekuma’s liquid silicone rubber LSR injection molding machine is versatile enough to meet the needs of a wide array of industries. In electronics, it is used to produce components like keypads, connectors, and insulators. The energy sector benefits from the machine’s ability to create durable seals and gaskets. Meanwhile, the food-grade industry relies on our LSR machines to manufacture safe, non-toxic kitchenware and utensils.

The adaptability of Dekuma‘s liquid silicone rubber LSR injection molding machines means they can produce a variety of components, including seals, arresters, and other highly specialized parts. By offering customization options, we ensure that our LSR injection molding machines can meet specific industry requirements while maintaining high-quality output.

Conclusion

Our liquid silicone rubber LSR injection molding machines exemplify excellence in manufacturing technology. With features designed for precision, efficiency, and versatility, these machines are transforming how industries approach production. The ability to produce high-quality components across multiple sectors, paired with advanced control systems, positions Dekuma as a trusted leader in the market. Companies looking to enhance their manufacturing capabilities will find in us a partner that prioritizes innovation and quality, ensuring we remain competitive in an ever-evolving landscape. As the demand for reliable and adaptable production solutions grows, we are poised to remain at the forefront of the LSR injection molding industry.