At Dekuma, we understand that liquid silicone rubber (LSR) is an essential material for many industries. The LSR injection molding machine plays a crucial role in shaping this versatile material into usable, high-quality components. But what makes this process so special? Let’s explore the details behind LSR injection molding machines and why they are a game changer in various manufacturing sectors.

The Role of LSR Injection Molding Machines

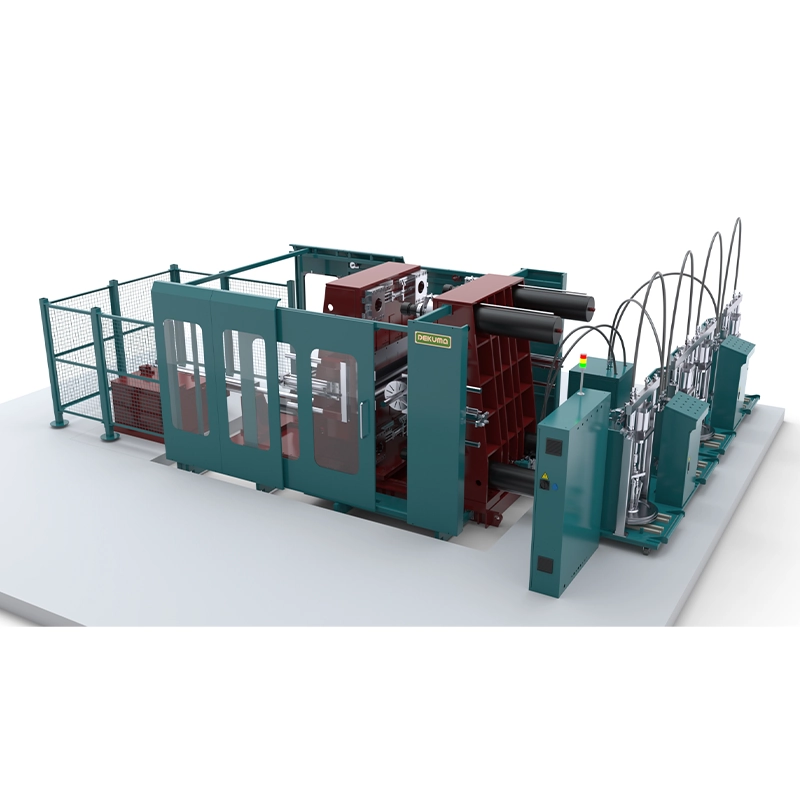

An LSR injection molding machine is designed to inject liquid silicone rubber into molds under high pressure. This process ensures that the material is precisely formed into parts like seals and gaskets. Unlike traditional thermoplastics, LSR maintains its flexibility, durability, and resistance to high temperatures, making it ideal for critical applications. At Dekuma, we ensure that our machines are equipped with an S98 smart B&R control system, which ensures precise operation and reliable performance. The system’s advanced automation and data analytics capabilities also empower manufacturers to achieve seamless production consistency, optimize cycle times, and significantly reduce material waste, ensuring high-value output across every batch.

How the Technology Behind LSR Injection Molding Works

The technology behind liquid silicone rubber injection molding machines involves several key components that work in unison. One of the most vital features is the patented synchronized dosing system, which ensures that the right amount of material is dispensed for each mold cycle. This results in consistent product quality and reduced waste. Additionally, the static mixer used in Dekuma machines ensures that the silicone components are perfectly blended, providing high consistency in each part produced.

Industries Benefiting from LSR Injection Molding

At Dekuma, we recognize that LSR injection molding machines are integral to industries like electronics, energy, and baby care. These machines are commonly used to manufacture electronic components, insulators, cable accessories, and even infant care products like bottle nipples. The ability to produce such a wide range of products with precision and speed makes the liquid silicone rubber injection molding machine a go-to solution for many manufacturing needs. By offering excellent durability, flexibility, and biocompatibility, LSR injection molding machines ensure that products meet the highest standards of performance and safety, making them a preferred choice for applications that demand quality and reliability.

Conclusion

For businesses seeking reliable and efficient production of liquid silicone rubber components, Dekuma’s LSR injection molding machines offer a perfect blend of advanced technology and practical features. With our S98 smart control system, synchronized dosing mechanism, and precise static mixer, we help customers improve productivity and maintain product quality. Trust Dekuma to provide innovative, cost-effective solutions for all your LSR molding requirements.