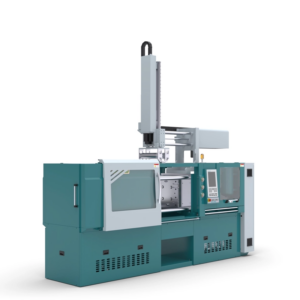

We at Dekuma are constantly committed to providing creative solutions that enable you to get the best possible product quality and manufacturing effectiveness. Our RC Series rubber injection molding machine is made especially for manufacturers who need to produce rubber parts including gaskets, oil seals, seals, and TPU components with accuracy, consistency, and dependability. The DKM-RC Series guarantees outstanding performance and satisfies the highest industrial standards, regardless of whether you need to create a sealing strip or a more intricate rubber component.

Precise Injection and Nozzle Control

The RC Series features an advanced plasticized injection system that separates the plasticized part of the system from the injected part. This separation ensures minimal contamination during the molding process, which is vital for maintaining the integrity and quality of your rubber parts. One of the key features of this system is the machine’s ability to lift the nozzle during vulcanization, preventing the molding material from being affected by excessive heat. This unique feature ensures that the injection volume remains precise, maintaining uniformity and consistency throughout production. These characteristics are particularly crucial when molding high-quality rubber components that must meet stringent specifications, such as automotive seals or medical-grade parts.

Flexibility for Different Production Needs

The DKM-RC Series provides exceptional flexibility to accommodate various production needs. One of the standout features of this rubber injection machine is the ability to be equipped with a double workstation and an optional mold transfer function, making it highly adaptable for different production setups. This versatility allows manufacturers to scale their operations and respond to fluctuating production volumes with ease. Whether you’re producing small, low-volume batches or running high-demand production lines, the RC Series offers the scalability and flexibility necessary to meet your operational requirements. The ability to configure the machine for different molding processes ensures you can achieve the best results for a wide range of rubber products.

High Precision with Servo Valve Control

For manufacturers who require absolute precision in their molding processes, the RC Series from Dekuma is equipped with a high-precision servo valve control injection system. This advanced system provides exceptional control over the injection process, ensuring precise, consistent, and repeatable results with every cycle. Whether you’re molding smaller components or larger, more complex parts, the servo valve control system ensures the highest degree of accuracy. This level of control is vital for producing rubber components that meet strict tolerances, ensuring that every product is of the highest quality.

Conclusion

For rubber molding applications that need accuracy, adaptability, and efficiency, Dekuma’s RC Series rubber injection moulding machines are the ideal choice. Our rubber injection machines offer the high performance and consistency necessary to produce high-quality rubber components because of their sophisticated features, which include accurate injection control, increased flexibility, and high-precision servo valve control. When combined with the knowledgeable assistance of our committed staff, Dekuma can help you increase your production capacity and accomplish exceptional outcomes in your manufacturing procedures.