Liquid Silicone Rubber (LSR) molding has become an essential manufacturing process, especially for industries requiring precision, flexibility, and safety in their components. Whether it’s for baby care products, food containers, or electronic components, the LSR injection molding machine is a game-changer. But what does the process involve, and how do machines like the Dekuma LSR molding machine contribute to its efficiency?

The Basics of Liquid Silicone Rubber Injection Molding

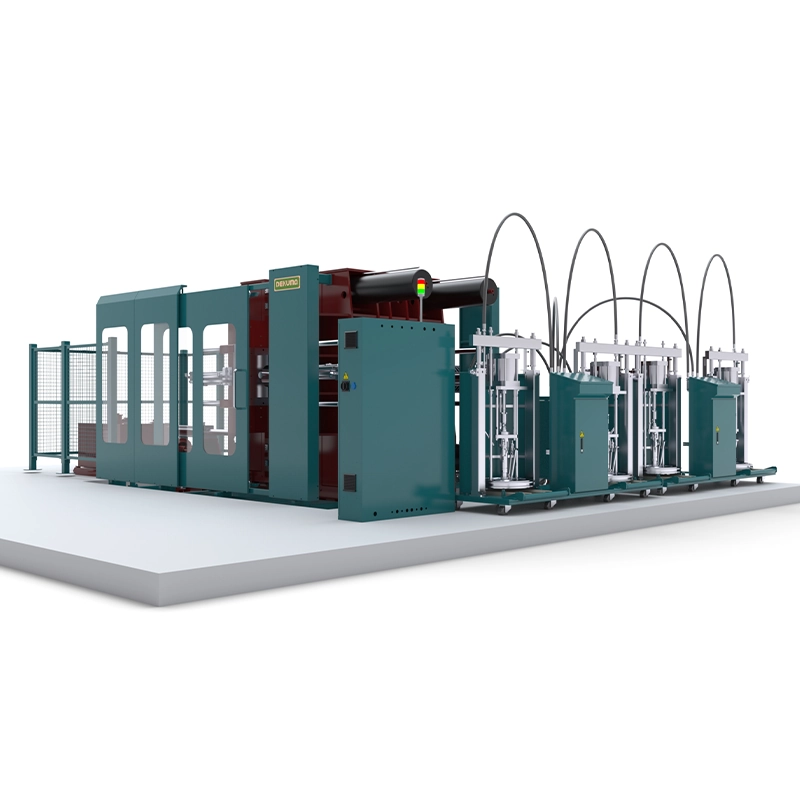

The process of LSR molding involves injecting liquid silicone into a mold under high pressure, where it solidifies to form the desired part. Unlike traditional plastic injection molding, LSR molding uses two components – silicone rubber A and B – that are mixed and then injected into the mold. The Dekuma LSR injection molding machine excels at ensuring that these two components are mixed with the utmost precision before they enter the mold, which is critical for the final product’s consistency and quality.

In the case of Dekuma’s LSR molding machine, a patented synchronized dosing system ensures that the silicone components are dispensed in the correct ratio and volume, making the molding process accurate and repeatable. This ensures that every part produced, whether it’s a baby bottle nipple or a kitchen utensil, meets strict industry standards.

The Role of the Synchronized Dosing System in LSR Molding

One of the standout features of the Dekuma LSR molding machine is the patented synchronized dosing system. This system is designed to inject the liquid silicone rubber components in a synchronized manner, which not only guarantees precise measurements but also contributes to the efficiency of the process. By ensuring that the right amount of each silicone component is injected, the system minimizes waste and reduces downtime, which makes production faster and more cost-effective.

This level of accuracy in dosing also allows for easy adjustments depending on the size or complexity of the molded product. Whether you’re creating soft-touch components or high-precision insulators, the Dekuma LSR injection molding machine makes sure the process remains seamless, improving both quality and productivity.

Importance of Consistent Mixing and Quality Control

An essential part of LSR molding is ensuring that materials A and B are mixed consistently. If not, it could result in uneven curing, bubbles, or defects in the final product. The Dekuma LSR molding machine includes an advanced static mixer, designed to ensure that the silicone components are thoroughly and evenly mixed before entering the mold.

This consistency is critical in industries where quality control is paramount, such as the food, baby care, and electronics sectors. With Dekuma’s LSR injection molding machine, manufacturers can rely on consistent results, improving the overall quality of their products and reducing the need for rework or waste.

Conclusion

At Dekuma, we pride ourselves on offering reliable and efficient LSR molding machines. The Dekuma LSR injection molding machine not only ensures high-quality products but also streamlines the production process, cutting costs, and boosting productivity. With features like the synchronized dosing system and advanced static mixer, we are committed to helping businesses across multiple industries achieve precision and consistency in their silicone rubber products. If you’re looking to improve your LSR molding process, our team is here to support you with the best solutions for your needs.