Custom rubber injection molding is a complex process, and choosing the right system can significantly impact the efficiency and quality of your production. Two of the most commonly used mold systems are the open mold and closed mold systems. At Dekuma, we specialize in creating custom solutions tailored to your unique needs. In this article, we will discuss the distinctions between these two systems and how they affect the custom rubber manufacturing process.

Open Mold Systems: Flexibility and Versatility in Custom Rubber Manufacturing

Open mold systems are often chosen for their flexibility in molding complex designs and large parts. They allow for quick changes in mold configurations and can be used for both small and large-scale production. At Dekuma, we understand that each customer’s needs are unique, so we offer customized solutions using open mold systems. This system is particularly beneficial when producing low-to-medium volume parts that require complex shapes, as it allows for easier access to the mold during the injection process.

However, while open molds offer versatility, they may not be the best option for high-volume production. The open mold process requires more frequent monitoring and adjustments to ensure quality and consistency across each cycle. This is why Dekuma’s advanced temperature control system and modular design can help ensure the performance of open mold machines by providing precise temperature regulation and optimized plasticization.

Closed Mold Systems: Efficiency and Consistency in High-Volume Production

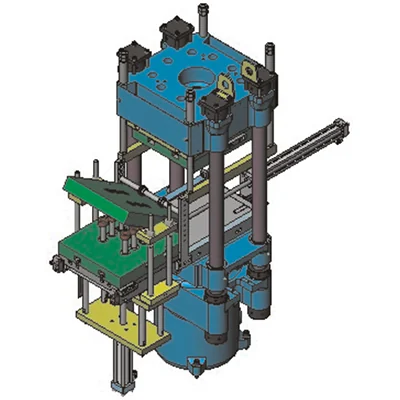

In contrast, closed mold systems are typically chosen for high-volume production due to their ability to maintain consistent part quality and reduce cycle times. These systems are fully enclosed, minimizing the risk of material contamination and ensuring a controlled environment for molding. The closed mold system is ideal for applications that require high precision and repeatability, making it the go-to choice for many industries.

As custom rubber manufacturers, we utilize closed mold technology with high-quality control systems, ensuring that the production process remains efficient and free from defects. The custom rubber injection molding machines we offer come equipped with three separate injection and clamping zones, each adjustable for optimal pressure and speed. This precision ensures that your custom rubber products meet the highest standards of quality and performance, even for the most demanding applications.

Choosing the Right Mold System for Your Production Needs

Choosing between open mold and closed mold systems for custom rubber injection molding depends on several factors, including part complexity, production volume, and desired precision. Dekuma’s expert team works closely with you to understand your unique needs and offer the best solution. Whether you’re looking for the flexibility of open molds or the precision of closed molds, we can help guide you toward the right choice.

The versatility of our systems, including our modular design and adjustable clamping zones, ensures that your production process is tailored to your specific requirements. Whether your focus is on small-batch custom rubber manufacturing or large-scale production, we have the technology and expertise to meet your needs.

Conclusion

When it comes to custom rubber manufacturers, selecting the appropriate mold system is crucial for achieving optimal production efficiency. Both open mold and closed mold systems have their benefits, and at Dekuma, we specialize in creating solutions that are custom-built to meet your specific needs. By leveraging advanced technology, modular design, and our team’s deep expertise, we ensure that your custom rubber injection molding process is streamlined, efficient, and cost-effective. Let Dekuma be your partner in creating high-quality, custom rubber products that meet the demands of your business.