Since our founding in 2004, we at Dekuma have been dedicated to pushing the boundaries of rubber injection molding technology. Over the years, we have developed an extensive range of solutions to meet the diverse needs of industries including automotive, power equipment, engineering vehicles, agricultural machinery, and defense applications. By leveraging our experience and technical expertise, we aim to provide innovative and reliable solutions for specialized applications such as insulators and rubber tracks.

Precision and Reliability in Custom Mold Machining

At Dekuma, precision is at the core of our approach to custom mold machining. Every mold is designed and manufactured by our experienced engineering team, ensuring tight tolerances and consistent performance. This attention to detail is especially critical for producing components like insulators, where material properties and dimensional accuracy directly affect safety and functionality. Our commitment to quality starts with carefully selected raw materials, all processed according to our stringent standards. By maintaining control over every step, we ensure that our molds not only meet but often exceed industry expectations.

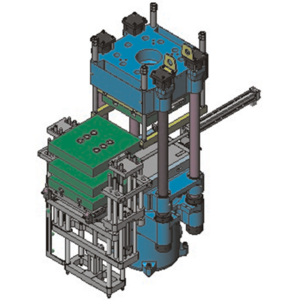

Tailored Solutions with Custom Molding Machines

We understand that each client’s needs are unique. That’s why our custom molding machines are engineered for flexibility and adaptability. From small-scale production to large, specialized components like rubber tracks for construction and agricultural machinery, our machines can be configured to handle specific requirements efficiently. By offering turnkey solutions, we simplify the production process for our clients, allowing them to focus on their core business while benefiting from our advanced technology. The modularity and scalability of our machines make it easier to expand production or modify processes without significant downtime or investment.

Innovation Driving Industry-Specific Applications

Specialized applications such as insulator manufacturing demand both innovation and consistency. Our technical team continuously develops new options and features that improve process stability, reduce waste, and optimize cycle times. For rubber track production, our solutions ensure uniform material distribution and precise dimensions, which are essential for durability and performance. By combining industry knowledge with engineering excellence, we help our clients achieve higher productivity and lower operating costs.

Conclusion

At Dekuma, we take pride in delivering complete, reliable, and innovative solutions in custom mold machining and custom molding machines. Our focus on specialized markets, from insulators to rubber tracks, ensures that our technology provides tangible benefits to our clients. By maintaining the highest standards in design, materials, and service, we continue to create value, supporting the growth and success of businesses worldwide. We are committed to advancing the capabilities of the rubber injection molding industry while driving innovation and practical solutions for every application.