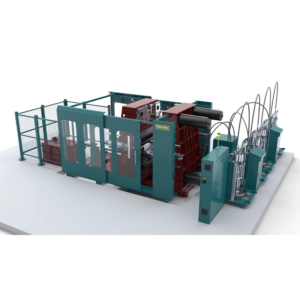

We at Dekuma are proud to provide rubber injection molding equipment that satisfies the varied and changing demands of different industries. The RT Series rubber injection molding machine is the ideal illustration of how creative design and precision engineering can combine to produce exceptional outcomes. The RT Series is well-suited for producing long-rod insulators, hollow core bushings, arresters, and cable accessories utilizing HTV (high-temperature vulcanized) silicone rubber because it was created especially for the creation of high-voltage composite insulators. Because of its versatility, it is a vital instrument for sectors including construction, automotive, and electrical power.

Robust Construction for Heavy-Duty Applications

The RT Series from Dekuma is built to withstand the demands of high-stress production environments. It features a highly reliable clamping unit designed with a block-type clamping style. This clamping unit ensures that the machine maintains stability throughout the production process, providing reliable performance even during the most challenging molding applications. The upper mold open structure of the RT Series not only reduces the operation height but also makes the machine more user-friendly, enhancing ease of use during the production process. In addition, the machine includes a hydraulic block for quick and precise mold height adjustment, offering increased flexibility to meet various production requirements and ensuring optimal results with each mold cycle.

Optimized Systems for Better Homogenization and Venting

To meet the needs of complex rubber molding, the RT Series incorporates a state-of-the-art plasticization system. This system has been optimized for superior screw delivery capacity, homogenization ability, and venting performance, which are essential for processing challenging materials like HTV silicone rubber. These enhancements ensure that even the most intricate molding applications are handled efficiently and consistently, maintaining high quality throughout the production process. The ability to effectively homogenize and vent materials during the injection process plays a critical role in producing parts that meet stringent industry standards.

Energy-Saving Technology for Cost Efficiency

At Dekuma, we are committed to providing rubber injection molding equipment that not only offers excellent performance but also helps manufacturers reduce operational costs and environmental impact. The RT Series features imported double-layer, high-temperature-resistant thermal insulation plates, which help to significantly reduce energy consumption by up to 40%. This energy-efficient design not only makes the RT Series more cost-effective but also helps reduce the carbon footprint of your manufacturing operations, promoting sustainability while delivering top-notch production efficiency.

Conclusion

Dekuma’s RT Series rubber injection moulding machine provides the ideal balance of accuracy, energy efficiency, and adaptability for companies in sectors including construction, automotive, and electrical power. The RT Series is a wise investment for any firm wishing to maximize production efficiency and guarantee reliable, superior results, regardless of whether they are producing insulators, bushings, or other rubber components. For contemporary rubber injection molding requirements, the RT Series is among the most dependable and adaptable choices due to its sturdy design, cutting-edge features, and energy-saving potential.