In today’s manufacturing world, efficiency, customization, and precision are key drivers for industries across various sectors. As businesses seek to optimize their production lines and create high-quality rubber products, rubber molding companies like Dekuma are stepping up to provide advanced solutions. The integration of custom rubber molding machines is crucial to meeting specific product requirements. By partnering with experienced custom rubber manufacturers, businesses can achieve seamless production processes and enhanced product quality.

Advanced Technology Behind Custom Rubber Machines

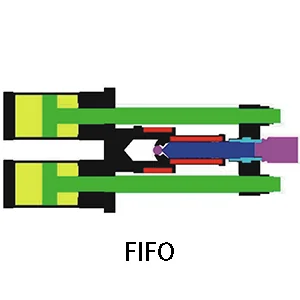

At Dekuma, we design our rubber molding machines with the latest technology to ensure optimal performance in every aspect of the production cycle. Our plasticizing and injection systems, optimized by German technical consultants, provide precise control over every detail of the molding process. By using advanced screws that slow down before plasticizing is complete and offering easy-to-disassemble injection pistons, we ensure that every part of the system is easy to maintain and operate.

The ability to adjust pressure and speed across multiple zones gives manufacturers full control over their production. Whether it’s the injection zones or the clamping system, the flexibility to adjust pressure settings is key to producing high-quality rubber components with excellent accuracy. This modular approach is tailored to meet the unique demands of various industries, making Dekuma an ideal partner for businesses looking to customize their manufacturing processes.

Customization for Unique Product Needs

Every customer has different product dimensions, weights, and production requirements, and Dekuma understands the importance of customizing machines to fit these specific needs. As custom rubber manufacturers, we can design injection molding machines that fit your product specifications perfectly. Whether it’s for producing small rubber parts or larger, more intricate designs, our machines provide the flexibility and precision needed for efficient production.

The modular design of our machines means that various options can be selected to meet specific production needs, further improving manufacturing efficiency. From temperature control systems that independently regulate the plasticizing and injection barrel temperatures to the specialized hydraulic and electric control systems, Dekuma ensures that all components work in harmony to achieve the desired results.

Ensuring Smooth Operation and Long-Term Durability

A significant part of the success of rubber molding companies is ensuring smooth and continuous operation over an extended period. Dekuma prioritizes the longevity of our machines by using high-quality electrical components from internationally renowned brands. Our industrial computers, proportional flow valves, and pressure control valves are carefully chosen to provide reliable operation without leakage or malfunction. This attention to detail ensures that our machines continue to perform at their best, minimizing downtime and maintenance costs.

Furthermore, our clamping system features adjustable low and high-pressure protection settings, which safeguard the machine from wear and tear. With multiple venting cycle settings and precise clamping stroke control, we aim to deliver consistent performance throughout the entire molding process. This approach not only improves production efficiency but also helps reduce overall maintenance costs.

Conclusion

Choosing the right rubber molding company can be a game-changer for your production line. At Dekuma, we understand the need for reliable, efficient, and customizable solutions. Our extensive experience in designing and manufacturing custom rubber molding machines ensures that our customers receive products that meet your specific needs. Whether you need advanced control systems, precise temperature regulation, or customizable molds, we are here to provide tailored solutions that help improve your production efficiency and product quality. With Dekuma, you can trust that your rubber molding needs are in capable hands, and we are committed to fostering long-term partnerships with our clients to achieve the greatest value. Let us work with you to create a customized solution that takes your business to the next level.