Injection molding is a highly efficient and versatile manufacturing process, but for it to function at its best, advanced control systems are essential. One of the most significant control systems used in modern injection molding machines is the Programmable Logic Controller (PLC). PLCs play a crucial role in streamlining operations, increasing precision, and enhancing the overall performance of machines. But how exactly does a PLC contribute to the process, and how does Dekuma, a prominent player among custom rubber manufacturers, optimize it for exceptional results?

What Is a PLC in Injection Molding?

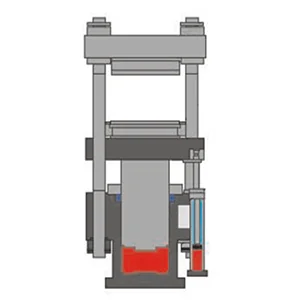

A Programmable Logic Controller (PLC) is a specialized industrial computer used to control various functions of an injection molding machine. In the context of injection molding, PLCs handle the complex processes of plasticizing, injecting, and cooling. This control system ensures that each step of the process happens with precision and consistency. The PLC can be programmed to control the speed, pressure, and temperature, adapting to different product requirements for custom mold machining.

The Role of PLC in Process Control

At Dekuma, we understand the critical role that PLCs play in making sure everything runs smoothly. With our custom rubber manufacturers expertise, we optimize our machines to allow the PLC to manage multiple processes simultaneously. This includes controlling three separate injection zones with adjustable pressure and speed, as well as the dwell zones. These precise control capabilities are essential for custom mold machining, where tailored solutions are often required to meet specific product dimensions or design features.

How Dekuma Uses PLCs to Enhance Machine Performance

We don’t just rely on generic solutions. At Dekuma, we ensure that each of our injection molding machines is designed and built with an efficient PLC system that is custom-configured for the unique needs of our clients. Our machines are equipped with German-made proportional flow valves and pressure control valves, all managed by a robust PLC system. This enhances reliability, reduces downtime, and ensures smooth operation across various cycles, making our systems ideal for custom mold machining projects.

Ensuring Quality with Advanced PLC Integration

Another key advantage of the PLC system is its ability to manage real-time data. This allows for continuous monitoring of performance and adjustments based on feedback. For custom rubber manufacturers like Dekuma, this means that we can fine-tune machines even during production, ensuring that the final product meets the highest quality standards. Whether it’s temperature control, speed regulation, or pressure adjustments, PLCs ensure our machines can meet complex and varying requirements.

Conclusion

At Dekuma, we’re not just about making machines; we’re about making machines work smarter. With our advanced PLC technology, we provide custom rubber manufacturers and custom mold machining services that are designed to meet the most exacting standards. By integrating top-of-the-line PLC systems into every machine, we ensure superior efficiency, precision, and durability. If you’re looking for injection molding machines that deliver consistent, high-quality results, Dekuma is your partner in innovation.