Liquid Silicone Rubber (LSR) injection molding machines have revolutionized the way many industries approach precision molding processes. With their ability to deliver high-quality, consistent results, LSR injection molding machines are becoming increasingly popular in various sectors. Here’s why our products are gaining traction and how Dekuma, as a leading LSR injection molding machine manufacturer, is making a significant impact in the industry.

Understanding LSR Injection Molding Machines

LSR (Liquid Silicone Rubber) is a versatile material that offers numerous benefits for molding applications. Unlike traditional silicone materials, LSR is in a liquid state at room temperature, allowing for precise and detailed molding. It’s often used in industries that require high-performance, durable, and flexible products.

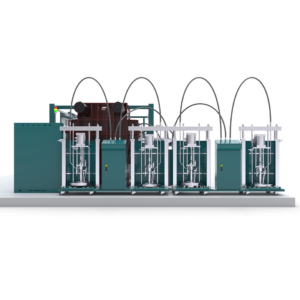

An LSR injection molding machine typically includes key components such as dosing pumps, static mixers, and a controlled injection system that ensures uniform flow and temperature. These features are crucial for molding intricate parts, such as seals, gaskets, and medical components. The ability to process liquid silicone ensures superior product quality, with minimal waste and enhanced efficiency.

One of the major reasons LSR has become the preferred choice is its ability to meet stringent industry standards while maintaining superior consistency in performance.

Top Industries Utilizing LSR Injection Molding Machines

The medical, automotive, and electronics sectors are the primary industries where LSR injection molding machines are widely used. In the medical field, LSR is used for manufacturing high-quality, biocompatible parts such as catheters, surgical tools, and masks. In infant care, it is used for products like pacifiers and nipples, ensuring safety and durability.

The automotive industry uses LSR for components like seals, gaskets, and vibration-damping parts. Electrical industries also benefit from LSR for items such as insulators and cable seals. Dekuma, as a prominent LSR injection molding machine manufacturer, plays a pivotal role in supplying machinery tailored to meet the precise demands of these industries. With years of experience, we have developed custom solutions that ensure optimal performance for each application.

Why Dekuma Stands Out Among LSR Injection Molding Machine Manufacturers

When it comes to LSR injection molding machine manufacturers, Dekuma stands out for its commitment to quality, precision, and innovation. With decades of experience in the molding industry, we offer customized solutions that cater to specific needs across various industries. Our turnkey systems ensure seamless integration, reducing downtime and optimizing production processes.

Dekuma’s LSR injection molding machines are designed with the latest technology, providing excellent control over temperature, pressure, and injection speed, which are crucial for producing high-quality LSR products. Our focus on continuous innovation and quality control makes our equipment reliable and cost-effective. Additionally, our global support network ensures that clients receive exceptional pre-sales, sales, and after-sales service, no matter where they are located.

Conclusion

Dekuma is at the forefront of LSR injection molding machine technology, offering industry-leading solutions for a variety of sectors, from healthcare to automotive. With advanced machinery and a commitment to customer satisfaction, we are the trusted partner for companies looking to implement or upgrade their LSR injection molding systems. Whether you need custom solutions or a full turnkey system, our expertise and global support make us the ideal choice for businesses seeking efficiency and precision in their manufacturing processes.