The process of vulcanization is crucial in determining the durability and performance of rubber tracks used in various applications, such as agriculture and construction. Rubber vulcanizing machine plays a pivotal role in this process, ensuring consistent quality and optimal curing. Understanding the link between vulcanizing precision and track durability is essential for any business aiming to produce reliable and long-lasting rubber components.

The Role of Precision in the Vulcanization Process

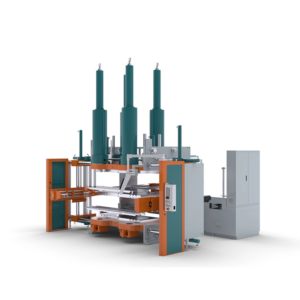

Precision is critical in the operation of our rubber vulcanizer machines. During vulcanization, the rubber undergoes a chemical process that transforms it into a durable material. Our rubber vulcanizing press machines are engineered to maintain precise temperature and pressure throughout the process, ensuring that the rubber is cured uniformly. This precision directly affects the strength and durability of the final product. By investing in high-quality vulcanizing equipment, businesses can significantly enhance the performance of their rubber tracks, thereby reducing the likelihood of wear and tear during operation.

Precision Vulcanization for Unmatched Track Durability

Another significant factor linking vulcanizing precision to track durability is the quality control integrated into Dekuma’s rubber vulcanizing machines. Our machines use advanced smart monitoring technologies that provide real-time data on critical parameters during the vulcanization process. This allows manufacturers to detect any deviations from specified conditions immediately. By maintaining strict quality control, we ensure that our rubber tracks meet the necessary durability standards. The enhanced durability resulting from precise vulcanization means fewer replacements and lower long-term costs for businesses reliant on high-performance rubber products.

Customization for Various Applications

At Dekuma, we recognize that different applications require different levels of durability. Our rubber vulcanizing press machines are designed to accommodate customization in the vulcanization process. By tailoring the parameters to meet specific requirements, we help businesses produce rubber tracks suited for various environments, from rough terrains to heavy-duty machinery. This level of customization not only improves track durability but also allows manufacturers to expand their product offerings and enter new markets. Our adaptability in design contributes significantly to the overall success of our clients.

Conclusion

In conclusion, the link between vulcanizing precision and track durability is undeniably critical in rubber production. By utilizing Dekuma‘s advanced rubber vulcanizing machines, businesses can ensure that their rubber tracks are not only high quality but also capable of enduring the rigors of their intended applications. Our commitment to precision, quality control, and customization in the vulcanization process translates into long-lasting rubber products that meet the needs of various industries. By investing in our rubber vulcanizing equipment, companies are setting themselves up for success in a competitive market, ensuring their rubber tracks are built to last.