For companies working with specialized rubber components, the equipment on the factory floor defines the boundaries of what is possible. At Dekuma, we focus on the details that make a significant difference in production. Our philosophy is built on the idea that a custom rubber machine must be more than a generic solution; it requires a dedicated partnership with a custom rubber machine manufacturer that understands nuanced application needs. This approach is evident in how we engineer our systems for precision, adaptability, and reliability.

Precision in Temperature Management

A core challenge in rubber manufacturing is maintaining exact thermal conditions throughout the process. To address this, our custom rubber machine design incorporates a Separate heat transfer oil system for the plasticizing and injection barrel. This architecture allows for different temperature control zones, which is critical for processing certain compound mixes. This separation ensures consistent material viscosity and prevents premature curing, directly contributing to the quality of the finished part, whether it is a complex insulator or a durable rubber track.

Adaptable Modular Machine Design

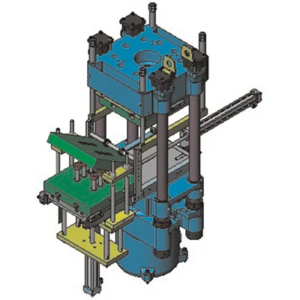

We recognize that no two manufacturing operations are identical. A production line for automotive seals has different demands than one for medical-grade components. Therefore, our machines adopt a modular design. This means all kinds of options can be selected for a customer’s different articles and unique process needs. This flexibility from your custom rubber machine manufacturer allows you to specify the exact configuration required for your specific product, ensuring the equipment aligns with your workflow from day one without unnecessary features or compromises.

The Foundation of a Reliable Control System

The operational consistency of a custom rubber machine depends on the integrity of its control and hydraulic systems. Our machines utilize a specialized industrial computer and software for command, with all electric and electronic component suppliers being well-known international brands. The hydraulic system employs an original German proportional flow rate valve, pressure valve, and direction valve. This combination guarantees smooth movement, eliminates leakage, and prevents wrong movements. World-famous sealing parts ensure this performance is endurable and without outer leakage, providing long-term operational stability.

For manufacturers in specialized sectors, the equipment must be a precise tool, not a general-purpose appliance. As a dedicated custom rubber machine manufacturer, Dekuma builds with this principle at the core. Our focus on targeted temperature control, adaptable modularity, and proven component quality provides a foundation for manufacturing specialized rubber products with consistency and confidence.