As a trusted LSR injection molding machine supplier, DEKUMA is dedicated to helping businesses transition to liquid silicone rubber (LSR) technology. With years of industry expertise and cutting-edge innovation, we ensure our machines deliver precision, efficiency, and reliability for a wide range of applications. Whether you’re in medical, automotive, or consumer goods, our solutions are tailored to meet your specific production needs. This step-by-step guide will walk you through the implementation process and highlight the advantages of using our machines. From initial setup to optimizing production workflows, we provide comprehensive support to maximize your investment in LSR technology.

Step 1: Assess Your Needs

The first step in implementing an LSR injection molding machine is to assess your production requirements. Understanding the specific applications for LSR, such as medical devices, automotive parts, or consumer goods, will help determine the right machine configuration. We recommend consulting with our team to evaluate your needs, ensuring the selected machine aligns with your production goals. As leading LSR injection molding machine factories, we provide tailored solutions that meet various industry demands.

Step 2: Choose the Right Equipment

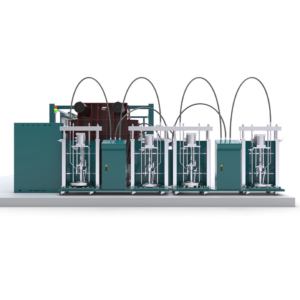

Once you have assessed your needs, the next step is to choose the appropriate LSR injection molding machine. At DEKUMA, we offer a range of models equipped with innovative technology, including smart control systems and high-precision dosing devices. These features enhance production efficiency and product quality. It’s essential to select a machine that can handle the specific properties of liquid silicone rubber, ensuring optimal performance in your manufacturing processes.

Step 3: Training and Setup

Proper training and setup are crucial for successfully implementing an LSR injection molding machine. Our team at DEKUMA provides comprehensive training for your operators, ensuring they understand the machine’s functionality and maintenance requirements. We also assist with the initial setup, helping to calibrate the machine for your specific production needs. This support is vital for achieving consistent results and minimizing downtime.

Conclusion

In conclusion, implementing an LSR injection molding machine involves careful assessment of your production needs, selecting the right equipment, and ensuring proper training and setup. As a leading LSR injection molding machine supplier, DEKUMA is committed to providing exceptional support throughout this process. Transitioning to LSR technology not only improves efficiency but also positions your business for success in today’s competitive market. Let DEKUMA guide you in harnessing the full potential of LSR injection molding. Contact us today to explore how our advanced machines and expert support can elevate your manufacturing capabilities and drive long-term growth.