When it comes to manufacturing rubber products, choosing the right molding technique can make a significant difference in the quality and efficiency of the final product. At Dekuma, we provide both rubber injection molding machines and injection rubber moulding machines, but how do these processes compare, and which one is the best for your production needs? In this article, we’ll explore the main differences in quality between rubber injection molding and transfer molding.

Rubber Injection Molding: High Precision and Efficiency

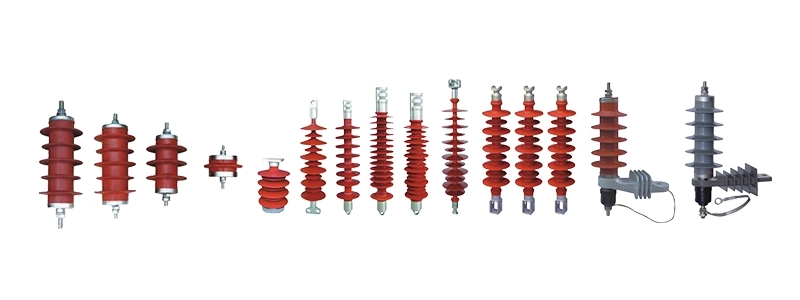

The rubber injection molding machine is an excellent choice for applications requiring high precision and efficient production processes. This technique uses hydraulic cylinders to feed the material directly into the mold, which allows for a quick and uniform injection process. With the Dekuma machines, you benefit from a simple structure that makes operation smooth and intuitive. The Dekuma rubber injection molding machines are particularly effective when producing long products, such as insulators and surge arresters, thanks to their functional design and accessibility from three sides.

In addition to speed and precision, rubber injection molding offers enhanced product consistency. The use of high-quality components, like the German-made hydraulic valves in Dekuma machines, ensures long-lasting and reliable performance. As a result, businesses can rely on consistent product quality without the risk of defects or discrepancies, making it an ideal choice for mass production.

Transfer Molding: Greater Flexibility with Design

On the other hand, transfer molding involves injecting rubber into a mold cavity from a separate chamber, providing more flexibility in terms of complex designs. This method is highly beneficial for products with intricate shapes or those requiring additional processes, such as adding inserts or overmolding. While transfer molding can be effective for specialized applications, it may require longer processing times and more complex tooling.

One key difference is that transfer molding can sometimes lead to more material waste and higher costs. The molding process requires more manual intervention and monitoring, which can make it less efficient for high-volume production. At Dekuma, we ensure that our injection rubber moulding machines are designed to minimize waste and improve operational efficiency, providing our clients with an optimized molding process.

Comparing Quality: Injection Molding vs. Transfer Molding

When comparing the overall quality of rubber injection molding to transfer molding, there are several factors to consider. The quality of the finished product often depends on the application and the specific requirements of the customer. Injection rubber moulding machines offer excellent control over the injection speed and pressure, leading to a higher level of uniformity in the product. In contrast, transfer molding may allow for more design flexibility but can result in more variation between products due to its complex nature.

For companies prioritizing consistent quality and efficiency in mass production, the rubber injection molding machine is usually the preferred choice. At Dekuma, our machines are engineered for precision, durability, and cost-effectiveness, providing a solution that meets the highest industry standards.

Conclusion

In the debate between rubber injection molding and transfer molding, it ultimately comes down to your production goals. If you need efficiency, consistency, and reliability, the injection rubber moulding machine from Dekuma is the ideal choice. For more complex designs requiring flexibility, transfer molding may offer advantages, though it comes with certain trade-offs in terms of efficiency and cost. By understanding the strengths and limitations of each technique, you can make an informed decision that best suits your manufacturing needs. At Dekuma, we are committed to providing high-quality molding solutions that ensure the best possible outcome for your production line.