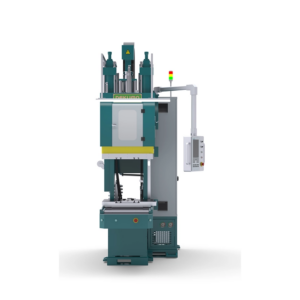

At Dekuma, we are aware that rubber molding requires accuracy. For this reason, we have taken great care in crafting our rubber injection molding machine. Rubber injection molding machines and the rubber injection machine in our RC Series offer exceptional accuracy, quality, and efficiency for everything from sealing solutions to automobile parts. Our RC Series machines are the ideal choice for your production requirements, whether you are producing intricate sealing joints, sealing strips, or precise rubber components.

Enhancing Efficiency with Flexible Design and Advanced Features

Efficiency is at the core of Dekuma’s RC Series machines. One of the key features that sets our rubber injection molding machines apart is the C-frame structure of the clamping unit. This accessible design makes it easy for operators to work from three sides of the machine, significantly reducing downtime and improving overall workflow. With the optional double workstations, production can be streamlined to achieve higher output while maintaining top-quality standards.

Another significant feature is the optional mold transfer function. This innovation allows for seamless operation in high-volume production environments, making it easier to manage multiple mold changes with minimal disruption to the process. Additionally, the high-precision servo valve control injection system ensures that every injection is perfectly controlled, improving part quality while reducing material waste.

Versatility Across Various Industries and Applications

The versatility of Dekuma’s RC Series rubber injection machine makes it an ideal choice for a wide range of applications. From automotive seals and precision rubber parts to TPU components, our machines are engineered to handle a variety of materials with ease. By offering features such as the ability to lift the nozzle during vulcanization, the RC Series machines ensure that your parts are processed at optimal conditions, guaranteeing the best possible outcomes for your production needs.

Whether you’re in the automotive, agricultural, or military vehicle industry, our rubber injection molding machines provide you with the consistency and quality you need to stay ahead in a competitive market. The combination of high-performance features and a user-friendly design means that you can focus on production, knowing that your machinery is working as efficiently as possible.

The Dekuma Advantage: Why Choose Us

At Dekuma, our mission is simple: to provide our clients with the highest quality rubber injection molding machines that are engineered for precision, performance, and reliability. Our rubber injection machines offer tailored solutions that meet the specific needs of each industry we serve. Whether you’re looking for a solution for complex sealing applications or precision rubber parts, we have you covered.

We pride ourselves on our dedication to customer satisfaction, ensuring that every machine we produce exceeds industry standards. Our team is committed to providing excellent service and support throughout the entire process, from initial consultation to post-installation. With Dekuma, you’re not just investing in a rubber injection molding machine – you’re gaining a trusted partner for your long-term success.

Conclusion

To sum up, Dekuma‘s DKM-RC Series rubber injection molding machines are the way of the future for rubber production. Our machines’ accuracy, adaptability, and dedication to innovation enable firms to easily accomplish their manufacturing objectives. Selecting Dekuma guarantees that your manufacturing lines are outfitted with state-of-the-art machinery that optimizes productivity and product quality. Put your trust in us to help you shape success.