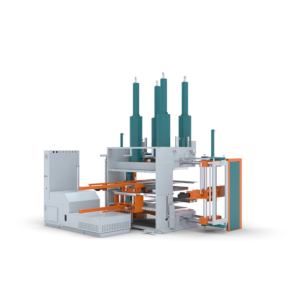

The mining industry demands high-performance rubber tracks that can withstand harsh conditions, and Dekuma‘s rubber vulcanizer machines are specifically designed to meet these challenges. By utilizing our specialized rubber vulcanizing press machines, mining operations can significantly extend the lifespan of their rubber tracks, leading to increased efficiency and reduced costs.

Superior Curing for Enhanced Durability

One of the primary benefits of using Dekuma’s rubber vulcanizing machines in the mining industry is the superior curing process they provide. Our rubber vulcanizer machines are engineered for precision, ensuring that each rubber track undergoes an optimal vulcanization process. This meticulous approach allows the rubber to achieve maximum strength and flexibility, essential for enduring the demanding conditions typical of mining sites. By investing in high-quality vulcanizing equipment, mining operators can produce tracks that are not only durable but also resistant to wear and tear, significantly extending their operational lifespan.

Consistent Quality, Fewer Failures

In the mining industry, consistency is key to maintaining productivity. Our rubber vulcanizing press machines incorporate advanced technology that guarantees uniformity in the manufacturing process. With features such as real-time monitoring and automated control systems, we ensure that every batch of rubber tracks meets the highest quality standards. This consistency reduces the likelihood of defects, which can lead to premature failure of the tracks. By utilizing Dekuma‘s technology, mining companies can operate with confidence, knowing that their equipment will perform reliably over time, ultimately resulting in lower maintenance costs and less downtime.

Customization for Specific Mining Applications

At Dekuma, we recognize that different mining applications may require customized solutions. Our rubber vulcanizing machine offers versatile mold designs that can be tailored to meet specific track specifications for various types of mining equipment. This adaptability is crucial in providing tailored solutions that enhance track performance in diverse mining environments. Whether mining for minerals or operating in rugged terrain, our rubber vulcanizer machines ensure that the tracks produced are optimized for their intended use. This level of customization not only improves track lifespan but also maximizes efficiency, enabling mining operations to achieve their production goals.

Conclusion

There is no denying the advantages of Dekuma’s rubber vulcanizing equipment for the mining sector. Our rubber vulcanizing press machines contribute to the longevity of rubber tracks used in a variety of mining applications by emphasizing outstanding curing, cutting-edge technology, and customization. For mining operators, purchasing Dekuma equipment results in decreased maintenance expenses, decreased downtime, and increased overall output. We want mining businesses to collaborate with us to improve their operations as we continue to innovate and create innovative solutions.