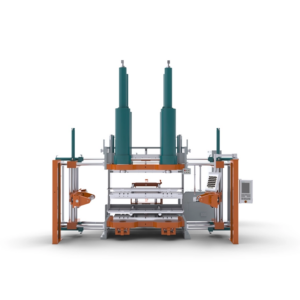

In the competitive world of rubber product manufacturing, achieving high efficiency and long-lasting durability is critical. Dekuma offers state-of-the-art rubber vulcanizing machines that help businesses boost their production capabilities while maintaining top-quality standards. As a trusted leader in the industry, our machines are equipped with advanced features that maximize performance and minimize operational costs, making them an essential investment for businesses in the rubber manufacturing sector.

High Automation: The Key to Cost and Time Efficiency

Dekuma’s rubber vulcanizing machines are known for their impressive level of automation. These machines are designed with automatic feeding, demolding, and material retrieval systems that reduce labor costs by up to 50%. By streamlining the process, companies can significantly reduce the amount of manual work required, making production both faster and more cost-effective.

The integration of automation also ensures consistent cycle times and minimizes downtime, allowing businesses to increase throughput while reducing the risk of human error. With these rubber vulcanizing machines, companies can expect seamless integration into their existing production workflows, optimizing overall efficiency without the need for complex adjustments or retraining.

Premium Quality Tracks for Long-Term Use

Dekuma‘s rubber vulcanizing machines are designed to produce high-strength, seamless rubber tracks suitable for a variety of applications, including agriculture, construction, and military sectors. Equipped with advanced mold-clamping systems and a constant-tension steel cord system, these machines create tracks that are 30-50% more durable than traditional rubber tracks.

These tracks not only offer superior strength but also have an extended service life, reducing the frequency of replacements and lowering maintenance costs. Whether it’s for use in heavy-duty machinery or rugged vehicles, our tracks provide lasting reliability even in the most demanding environments, ensuring that companies get the best return on investment (ROI) over time.

Real-Time Smart Monitoring for Superior Production Management

To take production management to the next level, we integrates our rubber vulcanizing machines with the iSee4.0 cloud platform, offering real-time data tracking and performance monitoring. This intelligent system allows businesses to oversee crucial production parameters, such as temperature, pressure, and energy consumption, in real-time.

With the easy-to-use B&R control system, operators can make precise adjustments and optimize performance without disrupting production. This proactive approach helps reduce unexpected downtime and maintenance costs, ensuring that operations run smoothly and efficiently. By integrating smart monitoring, businesses can ensure that their machines operate at peak performance levels, ultimately improving product quality and overall production efficiency.

Conclusion

Dekuma’s rubber vulcanizing machines represent the future of rubber track production, offering unmatched automation, premium quality, and cutting-edge monitoring systems. For businesses looking to enhance their manufacturing processes, investing in our rubber vulcanizing equipment ensures a competitive edge in an ever-evolving market.