Ensuring the quality of custom molded rubber products is a crucial step in the manufacturing process. At Dekuma, we understand the importance of providing products that not only meet the highest standards but also deliver reliability, durability, and performance for our clients. Whether it’s for automotive parts, industrial seals, or medical devices, our custom rubber manufacturers work diligently to ensure every product is up to par. This article explores the essential quality checks that we, at Dekuma, carry out before shipping our custom rubber solutions.

Inspecting Material Consistency

The foundation of any high-quality custom molded rubber product lies in the material used. At Dekuma, we ensure that every batch of rubber meets the exact specifications set by our customers. We carefully select materials based on their intended use, whether they require heat resistance, durability, or flexibility. Once the material is selected, our custom rubber manufacturers perform a thorough inspection to check for consistency in texture, hardness, and elasticity. This process guarantees that the product will perform well under the required conditions.

Testing Dimensional Accuracy

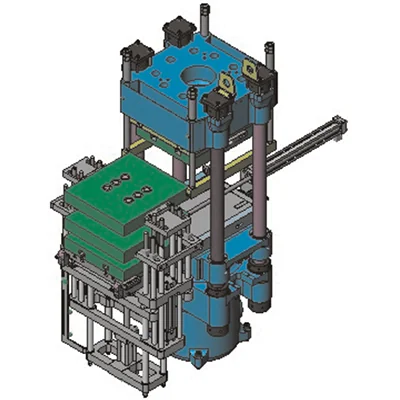

Precision is key when it comes to molded rubber products. To maintain the highest standards, custom rubber manufacturers at Dekuma conduct dimensional accuracy tests. This involves using specialized equipment to measure the mold and ensure that the rubber components match the design specifications. If any discrepancies are found, adjustments are made to the molding process to ensure the final product meets the customer’s exact dimensions. This attention to detail is what makes our custom molded rubber products reliable in all industries, from automotive to agriculture.

Durability and Performance Evaluation

Before we ship any custom molded rubber product, it undergoes a series of durability tests to ensure it performs as expected over time. At Dekuma, we simulate real-world conditions, subjecting the products to stress tests, wear-and-tear simulations, and environmental exposure, such as extreme heat, cold, or moisture. This step allows us to verify that our custom rubber manufacturers are delivering products that can withstand the rigors of their intended use, ensuring longevity and functionality for our customers.

Conclusion

At Dekuma, quality is at the heart of what we do. From selecting the right materials to performing precision checks and rigorous durability testing, we strive to exceed expectations. Our commitment to ensuring the quality of every custom molded rubber product we create is why our clients trust us to meet your specific needs. With a dedicated team and a focus on excellence, we continue to be the partner our customers rely on for durable and high-performing rubber solutions.