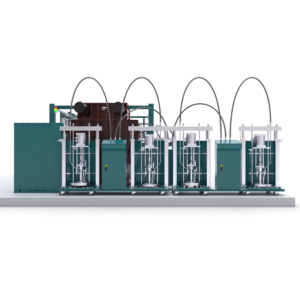

Dekuma’s rubber injection molding machines are the industry standard for producing high-quality rubber components, particularly in sectors where accuracy and reliability are critical. Numerous applications, such as electrical components, insulators, arresters, cable accessories, sealings, baby care products, and even kitchen items, can be accommodated by the technology of rubber molding machines. With features that guarantee effectiveness and adaptability, Dekuma’s injection molding equipment has emerged as the preferred option for producers globally, offering exceptional quality and dependability in a variety of sectors.

Precision and Control in Liquid Silicone Rubber Injection

One of the standout features of our Liquid Silicone rubber injection molding machine is the S98 smart B&R control system. By incorporating world-renowned electrical components, our machines offer superior reliability, minimizing the likelihood of electrical faults that can disrupt the production process. The system’s intuitive 10.4-inch color display and user-friendly man-machine interface allow operators to monitor production data and adjust settings with ease, ensuring maximum efficiency during operation. This enhanced precision control is essential for high-end applications, where even the slightest deviation can impact the quality of the final product.

Adaptability for Diverse Industries

Our rubber molding machine is incredibly versatile and capable of adapting to a broad range of industrial needs. Whether producing intricate electronic components or simple household items, the machine can be fine-tuned to meet specific production requirements. For instance, in the electronics industry, the machine delivers precise, high-quality components like cable accessories and insulators, which are crucial for ensuring the reliable functioning of electrical systems. The patented synchronized dosing device ensures continuous and accurate measurement, seamlessly adjusting to varying rubber injection volumes. This guarantees optimal material usage, reducing waste and improving production efficiency.

The machine’s ability to work with a wide array of materials makes it ideal for manufacturers in industries that require different types of rubber compounds. From high-performance products in the automotive sector to everyday items like kitchen articles, Dekuma’s molding machine provides the flexibility needed to excel in various markets.

Ensuring High-Quality Outputs

Another key feature that sets Dekuma’s machine apart is its high-precision static mixer. This advanced system ensures that materials A and B are evenly blended, a critical process in applications where uniformity is essential. The ability to deliver such precise and even mixtures makes Dekuma’s injection molding equipment the perfect solution for industries dealing with sensitive products, such as infant care items and food containers. Consistent, high-quality end products are a given, allowing manufacturers to meet stringent regulatory requirements and exceed customer expectations.

Conclusion

You can rely on Dekuma‘s Liquid Silicone rubber injection molding machine to ensure an accurate and efficient production process. Whether you’re producing common home items or intricate electronic components, our rubber molding equipment provides the adaptability, dependability, and quality required to satisfy a variety of industry standards. Dekuma continues to set the standard for cutting-edge rubber molding technology by offering remarkable precision control, versatility, and superior results, assisting producers in enhancing their processes and satisfying changing consumer needs.