The demand for efficient and reliable production of electrical insulators is ever-growing. As technology advances, manufacturers seek machines that can handle complex materials and deliver consistent results. One such solution that stands out in this field is the Dekuma insulator making machine. This machine is designed to produce high-quality insulators and other electrical components with precision and reliability.

What Makes the Dekuma Industrial Insulator Molding Machine Stand Out?

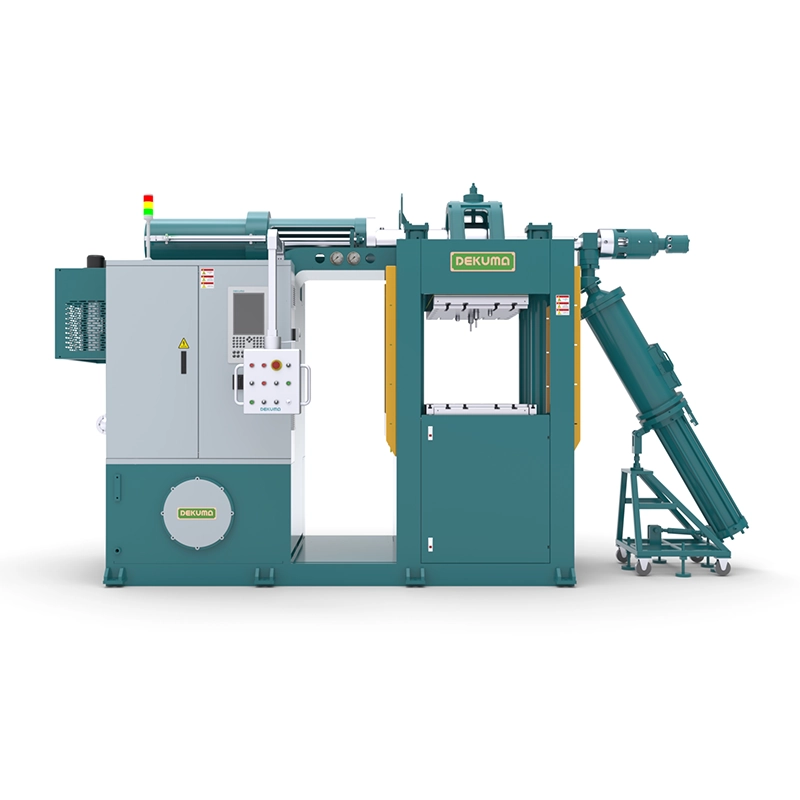

At Dekuma, we focus on delivering solutions that help streamline the production of insulators. The industrial insulator molding machine from Dekuma is purpose-built for manufacturing high-voltage composite rubber insulators. It handles various rubber materials, such as silicone rubber and Ethylene Propylene Diene Monomer (EPDM), ensuring excellent product quality in every cycle. Our machine’s advanced technology and solid design make it a trusted choice in the industry. This flexibility, combined with our comprehensive technical support, allows manufacturers to optimize their insulator production for diverse specifications while consistently achieving superior electrical and mechanical performance.

Key Features of the Insulator Making Machine

One of the standout features of the insulator making machine by Dekuma is its advanced material plasticization and injection system. This system has been designed to ensure that rubber compounds are consistently and evenly mixed, providing superior homogenization. The machine also integrates a double-layer thermal insulation plate to ensure that energy consumption is significantly reduced by approximately 40%. This contributes to higher operational efficiency and reduces thermal stress on components, which increases the longevity of the machine.

Versatility and Precision in Production

The Dekuma industrial insulator molding machine is known for its versatility in handling different rubber materials. The machine’s robust and reliable hydraulic system, equipped with American high-pressure pumps and German hydraulic valves, ensures smooth and consistent performance. This configuration guarantees that every component produced meets the highest standards of quality. Additionally, the high-precision stroke measurement system ensures that mold positioning, shot sizes, and switching points are accurate, which is essential for creating complex and precise insulator shapes.

Conclusion

At Dekuma, we understand the challenges of insulator production, and that’s why our insulator making machine is designed to offer stability, efficiency, and versatility. Whether you’re producing hollow core insulators, long rod insulators, or surge arresters, our industrial molding machines provide a reliable solution to meet your production goals. Reach out to us today to discover how our Dekuma industrial insulator molding machine can elevate your manufacturing processes. Through precise pressure control and automated molding cycles, our machines ensure product uniformity and repeatability, enabling you to scale production with confidence while maintaining stringent quality standards.