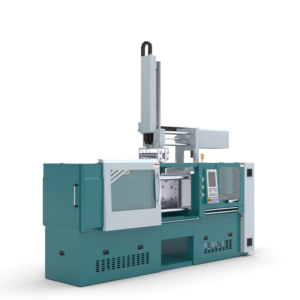

At Dekuma, we pride ourselves on leading the way in innovative manufacturing solutions, particularly with our RH Series Rubber Injection Molding Machine, Dedicated to Sealing Ring production. In this article, we will explore the unique features of our rubber horizontal injection molding machine, designed to meet the specific needs of industries requiring precision and efficiency.

High Efficiency and Consistency

Our RH horizontal rubber injection molding machine is engineered for maximum efficiency. It is equipped with automatic brushes for product pickup and mold cleaning, which significantly enhances production processes. For sealing rings production, this feature helps improve product yield, reduce flash and defect rates, and extend mold service life. By minimizing downtime and maximizing output, our horizontal molding machine stands out as a reliable choice for manufacturers seeking high consistency in their rubber parts. We understand that industries demand rapid production cycles without compromising quality. Therefore, our horizontal rubber injection molding machine is built to deliver fast cycles and tight tolerances, all while ensuring the integrity of the materials used. By incorporating advanced technology, we enhance the overall process, making it easier for businesses to scale their operations.

Advanced Features for Optimal Performance

One of the standout features of our RH Series Rubber Injection Molding Machine is its first-in, first-out injection system. This design is crucial for preventing rubber from remaining in the barrel for extended periods, which minimizes the risk of over-vulcanization. Such considerations are essential for maintaining material stability in any horizontal rubber injection machine setup. Additionally, our machine can process various types of rubber, including natural rubber, nitrile rubber, and fluoro rubber. This versatility allows manufacturers to produce sealing rings and other rubber parts tailored to their specific applications. The horizontal rubber injection machine is thus an invaluable asset in sectors ranging from automotive to consumer goods, where precision and reliability are paramount.

Custom Solutions for Diverse Industries

At Dekuma, we understand that every industry has unique demands. Our horizontal rubber injection molding machine is designed specifically for producing sealing rings and other rubber components, ensuring that our clients receive a tailored solution that meets their needs. We collaborate closely with our clients to understand their requirements and offer customized setups that enhance productivity and efficiency. Whether you are in the automotive sector, electronics, or any field requiring high-quality rubber products, our RH Series Rubber Injection Molding Machine can be adapted to fit your production goals. By investing in our technology, businesses can expect to see improvements in both production speed and product quality, ultimately leading to greater customer satisfaction.

Conclusion

In conclusion, Dekuma is committed to revolutionizing the rubber injection molding industry with our rubber horizontal injection molding machine. We combine innovative technology with a deep understanding of industry needs to deliver solutions that improve efficiency, consistency, and product quality.