At Dekuma, we are proud to lead the way in the rubber track production industry. Our commitment to innovation and quality has resulted in the development of advanced machinery that meets the diverse needs of our clients. We specialize in providing solutions for Rubber Track Production Line that caters to various applications, such as suitable for agriculture tracks, construction tracks, military tracks, and snowmobile tracks.

High Automation for Enhanced Efficiency

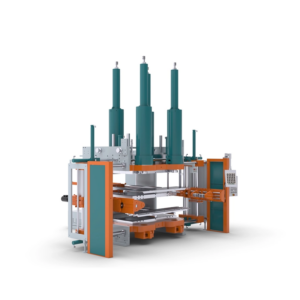

The cornerstone of our production line is high automation. Our rubber track molding machine is designed to streamline the manufacturing process, significantly reducing the need for manual labor. With automation, we have managed to save about 50% of the labor force compared to traditional machines. This not only optimizes productivity but also enhances the consistency of output quality. By integrating smart monitoring systems, we ensure that every track produced meets our stringent quality standards. Our rubber track building machine also features reliable technology that allows for continuous iterating on designs and processes. This adaptability ensures that we can meet the evolving needs of our clients in sectors ranging from agriculture to military applications. As we implement these advanced features, we remain committed to improving efficiency and reducing production costs.

Clever Curing Shutdown for Optimal Performance

One of the standout features of our rubber track production line is the clever curing shutdown mechanism. This technology allows for precise control over the curing process, ensuring that every track achieves optimal performance. The key to consistent quality is our machine’s unique design, which integrates the vulcanizing unit with an automatic tensioning system. This innovation enables us to produce completely seamless, one-piece tracks. Eliminating traditional joints, which are common points of failure, enhances the durability and longevity of our tracks. Clients can trust that the rubber track machine we offer will deliver joint-free tracks with highly uniform performance. This is particularly crucial for demanding applications where reliability is non-negotiable, such as in construction and military settings.

Continuous Iterating for Innovative Solutions

At Dekuma, we embrace a philosophy of continuous improvement. Our team is dedicated to iterating on our existing technologies to create even better products. The rubber track building machine at the heart of our operations is a testament to this commitment. With features like automatic rubber loading, automatic demoulding, and automatic material retrieval, our production line is not only efficient but also user-friendly. By focusing on innovation, we can respond to the needs of our clients in real-time, developing tailored solutions that address specific challenges. Whether it’s enhancing the performance of suitable for agriculture tracks or optimizing tracks for snowmobiles, our continuous iterating process ensures that we stay ahead of the competition.

Conclusion

In conclusion, we at Dekuma are excited about the future of rubber track production. With our trusted rubber track molding machine and rubber track building machine, we are setting new standards in efficiency, quality, and innovation. Our high automation processes, clever curing shutdown mechanisms, and commitment to continuous improvement position us as leaders in the industry.