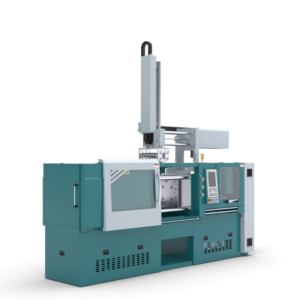

Manufacturing specialized equipment requires a deep understanding of end-use applications. At our Dekuma factory, we see the development of our RH Series horizontal rubber injection molding machine as a response to specific industry needs. This model, dedicated to sealing ring production, incorporates technologies that target common production challenges. As a horizontal molding machine factory, our goal is to provide tools that offer tangible improvements in precision and efficiency for our clients.

The Benefit of High-Pressure Injection

A core feature built into this Dekuma horizontal rubber injection molding machine is an ultra-high-pressure injection system. This capability is important for ensuring material completely fills intricate mold cavities, which is a common requirement for detailed sealing ring profiles. The system delivers the necessary force to achieve this without compromising the cycle time. This function of the horizontal molding machine supports the production of dense, consistent parts with complex geometries, which is an expected outcome for manufacturers in this field.

Cold Runner Technology for Material Efficiency

To address material waste and labor, this horizontal rubber injection molding machine can be equipped with cold runner mold technology. Unlike traditional methods, a cold runner system helps manage the material feed channel to prevent vulcanization. This design reduces the amount of scrap material generated per cycle, as the rubber in the runners remains usable. For a high-volume production environment, this feature of the horizontal molding machine can contribute to lower raw material costs and reduce downtime for cleaning.

A Unified System for Process Stability

The integrated injection unit on this horizontal molding machine is designed as a cohesive system. This integration supports a more consistent plasticization and injection process, which is a fundamental requirement for repeatable part quality. The design minimizes potential fluctuations in temperature or pressure that can occur in less unified systems. This approach to building a horizontal rubber injection molding machine provides a stable foundation for the production process, aiming for uniformity in every batch.

Conclusion

The decisions made in a horizontal rubber injection molding machine factory influence daily production on the shop floor. At Dekuma, the features of our RH Series—including ultra-high pressure injection, cold runner compatibility, and an integrated unit—are selected for their practical impact. This horizontal rubber injection molding machine is constructed to support the manufacture of high-quality sealing rings. We focus on providing machinery that incorporates specific technologies to meet the demands of modern rubber part production.