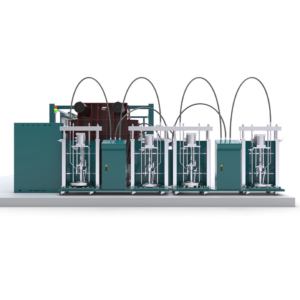

We at DEKUMA are pleased to be a top supplier of LSR injection molding machines, providing cutting-edge equipment built for accuracy and efficiency. Our clients can manufacture high-performance liquid silicone rubber (LSR) products because to our dedication to quality. LSR devices might, however, have problems, just like any other sophisticated equipment. This article offers a thorough how-to for resolving typical issues with LSR injection molding machines.

Identifying Common Problems

The first step in troubleshooting is to identify the common issues that may arise during the operation of an LSR injection molding machine. Some frequent problems include inconsistent material flow, poor part quality, and machine downtime. Understanding these issues is crucial for effective resolution. We recommend keeping a log of any irregularities during production, as this can help diagnose the underlying causes. Our experience as one of the top LSR injection molding machine factories allows us to recognize these issues quickly.

Checking Equipment Settings

Once the problems have been identified, the next step is to check the machine settings. Ensure that the temperature, pressure, and injection speed are set according to the specifications for the liquid silicone rubber being used. Incorrect settings can lead to defects in the molded parts and affect overall production efficiency. At DEKUMA, we emphasize the importance of regularly reviewing and adjusting these parameters to maintain optimal performance. If necessary, consulting the machine manual or reaching out to our support team can provide additional guidance.

Regular Maintenance and Care

Another critical aspect of troubleshooting is regular maintenance and care of your LSR injection molding machine. Routine checks on components such as the mixing unit, dosing system, and molds can prevent many common issues from arising. Keeping the machine clean and addressing wear and tear promptly can significantly enhance its longevity and performance. We at DEKUMA offer maintenance packages and support to ensure that your equipment remains in peak condition, minimizing unexpected downtimes and maximizing productivity.

Conclusion

In conclusion, troubleshooting common issues in LSR injection molding machines involves identifying problems, checking equipment settings, and performing regular maintenance. As a trusted LSR injection molding machine supplier, DEKUMA is dedicated to providing the support and expertise needed to keep your machines running smoothly. By following these steps, manufacturers can enhance productivity, improve product quality, and extend the life of their equipment. Our commitment to excellence ensures that you have the best tools and resources available for your LSR injection molding needs.