At Dekuma, we understand the importance of maximizing floor space efficiency, especially in a competitive manufacturing environment. Our team of experts works tirelessly to design customized injection molding machines that not only meet your production needs but also save valuable space in your facility. Manufacturers today are constantly looking for ways to enhance productivity while minimizing operational costs, and custom rubber manufacturers are no exception. One of the most significant ways to achieve this is through the optimization of floor space. Let’s take a look at how a customized injection molding machine can contribute to this goal.

Compact Design and Modular Flexibility

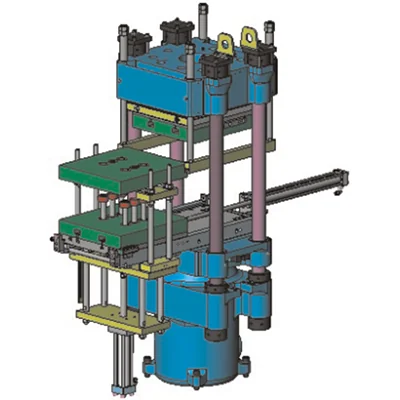

A customized injection molding machine offers a level of modularity that is not available with standard machines. At Dekuma, we work with you to create a machine that fits your specific product and process requirements. Our modular design allows you to choose various options that optimize your layout. This design flexibility enables you to create a production line that maximizes available floor space without sacrificing performance.

By tailoring the size and configuration of each machine, we can ensure that you are using your space as efficiently as possible. Whether you are producing large quantities of custom rubber products or running multiple smaller jobs, our machines fit seamlessly into any production facility.

Efficiency in Material Flow and Equipment Placement

One of the key ways that customized injection molding machines help maximize floor space is through their ability to streamline material flow and equipment placement. Dekuma designs machines with precise clamping and injection zones that can be adjusted to your needs, meaning you don’t need extra equipment cluttering up the workspace.

By ensuring that all components of the custom rubber manufacturers equipment are optimized for efficient material handling, we can help eliminate bottlenecks and optimize workflow. This not only reduces the space required for each task but also cuts down on time spent moving materials between different stages of the process.

Robust Performance with a Smaller Footprint

Our customized injection molding machines at Dekuma are engineered to deliver outstanding performance in a compact footprint. With advanced technology, including German-made proportional flow valves and high-precision temperature control, our machines perform efficiently without requiring excessive space.

The ability to achieve high productivity in a smaller area is a significant advantage for custom rubber manufacturers looking to maximize their production space. By offering custom solutions, we ensure that our machines are not only space-efficient but also highly durable, reducing the need for frequent maintenance and further space requirements for repairs or replacements.

Conclusion

Maximizing floor space in your manufacturing facility is more critical than ever. By working with Dekuma and investing in a customized injection molding machine, you can streamline your operations and optimize your space. Our specialized designs ensure that you are getting the most out of your available square footage while maintaining high levels of productivity and performance. If you’re looking to improve efficiency and reduce operational costs, Dekuma is here to help you achieve those goals.