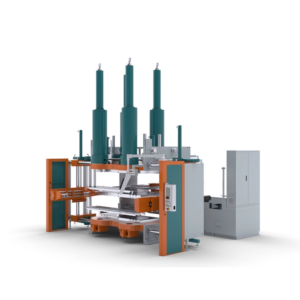

Our Rubber Track Production Line exemplifies how our rubber vulcanization machines can help businesses maximize their return on investment (ROI). With automated processes and energy-efficient designs, our production line reduces downtime and operational costs while delivering superior output. By focusing on advanced technology and operational efficiency, we empower our customers to achieve impressive results. Whether you’re in tire manufacturing, industrial rubber products, or specialized rubber components, DEKUMA provides reliable solutions tailored to your needs.

Invest in High-Quality Rubber Vulcanizing Machines

One of the key factors in maximizing ROI is investing in high-quality rubber vulcanizing machine. Our innovative rubber vulcanizer machines are designed for durability and performance, ensuring that they withstand the demands of continuous operation. By choosing DEKUMA, businesses gain access to advanced features that enhance productivity and reduce downtime. This initial investment pays off over time as the efficiency of our machines leads to increased output and lower production costs.

Optimize Production Processes

Efficiency in production processes is essential for maximizing ROI. Our rubber vulcanization machine integrates cutting-edge technology that streamlines operations, from the initial mixing of rubber to the final vulcanization stages. With precise control over temperature and pressure, our machines ensure optimal curing conditions, resulting in high-quality rubber tracks. By reducing cycle times and minimizing waste, our rubber vulcanizing equipment allows manufacturers to produce more in less time, significantly enhancing profitability.

Maintain and Upgrade Your Equipment

Regular maintenance and timely upgrades are crucial for maximizing the benefits of any rubber vulcanizing machine. At DEKUMA, we provide comprehensive support and resources to ensure that our rubber vulcanizer machine operates at peak performance. By adhering to maintenance schedules and leveraging our expertise for upgrades, businesses can extend the lifespan of their equipment. This proactive approach not only safeguards the initial investment but also contributes to sustained efficiency and output, further boosting ROI.

Conclusion

Maximizing ROI with DEKUMA’s rubber vulcanizing equipment is achievable through strategic investment, optimization of production processes, and diligent maintenance. Our advanced machinery is designed to minimize waste, reduce energy consumption, and streamline workflows, allowing businesses to achieve higher productivity with lower operational costs. Our rubber vulcanizing machines are engineered to deliver exceptional performance and reliability, ensuring that businesses can thrive in a competitive market. With customizable solutions and industry-leading automation, we help manufacturers adapt to changing demands while maintaining consistent quality standards. By partnering with DEKUMA, manufacturers can enhance their operational capabilities and enjoy significant returns on their investments in rubber vulcanization technology.