When it comes to maintaining your rubber injection molding operation, having the right equipment is key. Over time, even the best machines can show signs of wear and may struggle to keep up with evolving demands. At Dekuma, we specialize in providing high-quality rubber injection molding machines and rubber moulding machines, ensuring that you’re always one step ahead of the competition. In this article, we’ll discuss how to recognize the signs that it might be time to upgrade your old machine.

Is Your Machine Struggling with Efficiency?

One of the first signs that your rubber moulding machine needs an upgrade is a noticeable decrease in productivity. Older machines tend to have slower cycle times, which means you’re losing valuable production hours. If you’re finding it harder to meet customer demands or keep up with industry trends, it’s time to evaluate whether your machine can handle the workload. Upgrading to a rubber injection molding machine with an optimized injection system and enhanced cycle time can make a significant difference in both efficiency and output.

Increasing Maintenance Costs Are Eating into Your Budget

Another red flag is the rising cost of repairs and maintenance. As machines age, they become more prone to breakdowns, and the parts can become harder to source. If your rubber molding machine is in constant need of repairs, this not only impacts your bottom line but also causes delays in your production line. An upgrade to a newer model, like the RT Series Rubber Injection Molding Machine, which features an Austrian-made B&R control system, can greatly reduce the need for frequent maintenance.

Changes in Product Quality or Consistency

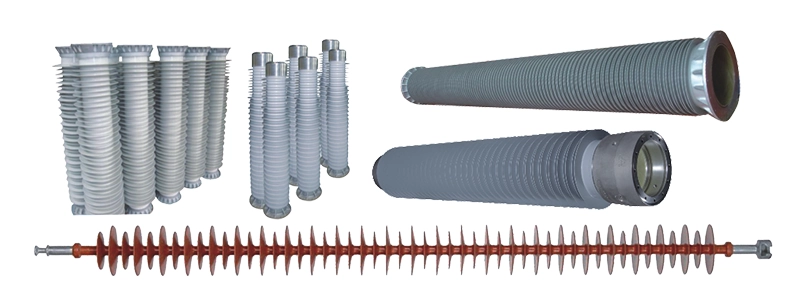

Over time, even the best machines may struggle to maintain the same level of precision and consistency. This can result in defects, poorly molded products, or inconsistent material flow, ultimately affecting your product’s quality. If you notice issues with product integrity, it’s time to consider an upgrade. The RT Series Rubber Injection Molding Machine is designed to handle HTV silicone rubber with great precision, making it ideal for producing components like insulators, bushings, and cable accessories.

Conclusion

Upgrading your rubber moulding machine may seem like a significant investment, but in the long run, it can save you time, money, and improve your product quality. At Dekuma, we are committed to providing advanced solutions like the RT Series Rubber Injection Molding Machine, which brings enhanced efficiency, reduced maintenance, and improved product consistency. Don’t let outdated equipment slow you down—invest in the right technology to meet today’s production demands and stay competitive in the market.