As the trend toward smart factories continues to grow, our rubber vulcanization machines are designed to support this industrial evolution.. These advanced machines not only improve production efficiency but also ensure superior product quality, especially for rubber tracks used across various industries.

Integration of IoT Technologies

Smart factories thrive on data and connectivity, and our rubber vulcanizing press machines are designed to integrate seamlessly with Internet of Things (IoT) technologies. By embedding smart sensors and monitoring systems in our vulcanizing equipment, we enable real-time data collection during the rubber vulcanization process. This allows manufacturers to monitor critical parameters such as temperature, pressure, and curing times from anywhere, ensuring that every product meets the highest standards. The data-driven approach empowers factories to make informed decisions, optimize processes, and reduce waste, aligning perfectly with the goals of a smart manufacturing environment.

Enhanced Automation for Streamlined Operations

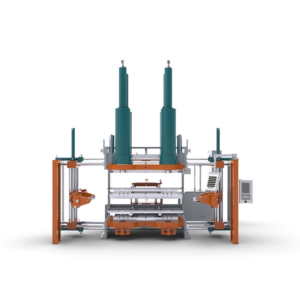

One of the hallmarks of a smart factory is automation, and our rubber vulcanizing machines exemplifies this principle. At Dekuma, we design our rubber vulcanizer machines to automate key processes, reducing the need for manual intervention and minimizing the risk of human errors. With features such as automatic mold changes, precise heating and cooling cycles, and self-adjusting settings, our rubber vulcanizing press machines operate with remarkable efficiency. This level of automation not only accelerates production timelines but also enhances the consistency and quality of rubber tracks, helping businesses meet increasing demand with ease.

Predictive Maintenance for Increased Uptime

In a smart factory, downtime is a major concern, and we address this challenge with our advanced rubber vulcanizing equipment. Our machines are equipped with predictive maintenance capabilities that monitor the health of each component in real-time. By analyzing data trends, we can forecast potential issues before they lead to breakdowns. This proactive approach ensures that our rubber vulcanizing machines remain operational, enhancing overall factory productivity. Clients can minimize costly disruptions in their production lines and achieve greater reliability in their rubber tracks, which is vital for maintaining competitiveness in today’s fast-paced market.

Conclusion

In summary, smart factories are redefining the landscape of rubber manufacturing, and Dekuma’s vulcanizing equipment is a crucial part of this transformation. By integrating IoT technologies, enhancing automation, and implementing predictive maintenance, our rubber vulcanizing machines empower businesses to achieve higher efficiency and superior product quality. As the manufacturing industry evolves, we remain committed to providing the cutting-edge solutions needed to thrive in a smart factory environment.