At Dekuma, we understand the crucial role that rubber track machines play in ensuring durability, efficiency, and precision in the production of rubber tracks. These machines are essential in various industries, from agriculture to electric and defense, providing vehicles and machinery with the traction and strength they need to operate in tough environments. But how do rubber track molding machines work to deliver such high-performance results? Let’s dive into the process.

The Core of Rubber Track Production

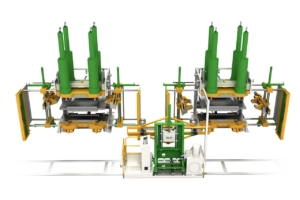

At the heart of every rubber track lies a highly specialized manufacturing process. Rubber track machines are designed to produce tracks that are tough enough to withstand harsh conditions, all while maintaining their flexibility and traction. The rubber track molding machine plays a central role in this process, ensuring that each track is molded precisely to meet the operational needs of industries. With the Dekuma machines, the production process starts with mixing the appropriate rubber compounds and other materials. These are then fed into the machine, where the molding takes place. The precision of our machines ensures that every track fits the specifications required by various industries, ensuring both strength and durability.

Shaping and Curing for Long-lasting Performance

The process of shaping the rubber tracks is crucial to their performance. A rubber track molding machine uses advanced molding techniques to create tracks that maintain their integrity even under extreme stress. At Dekuma, we use a combination of heat, pressure, and precise timing to cure the rubber. This ensures the rubber undergoes a chemical change that makes it strong and durable, capable of handling the weight and strain that vehicles and machinery place on it. The uniform curing process guarantees that every rubber track coming out of our machines performs reliably in various applications, whether in rough agricultural fields or construction zones.

Automation and Efficiency in Manufacturing

Our rubber track machines are equipped with cutting-edge automation technology to ensure that the production process is both fast and efficient. At Dekuma, automation is at the forefront of our design philosophy. The machines can produce high-quality rubber tracks with minimal manual intervention. This not only speeds up production but also reduces the chance of human error, ensuring that every batch is consistent and reliable. The automation technology also helps reduce energy consumption and downtime, making the production process more environmentally friendly and cost-effective for our partners.

Enhancing Production Capabilities

In the ever-evolving industrial landscape, it’s important for businesses to stay ahead of production demands. Rubber track molding machines from Dekuma are designed to be scalable, making them ideal for companies looking to increase production volumes without sacrificing quality. By combining high-speed automation with precision engineering, we ensure that our machines can meet both small-batch and large-scale production needs. Additionally, our focus on energy efficiency means that businesses can reduce costs and enhance profitability, all while producing top-notch rubber tracks that meet stringent industry standards.

Conclusion

At Dekuma, we are committed to providing innovative solutions that improve the efficiency, reliability, and scalability of rubber track production. Our rubber track molding machines are engineered to deliver precision and durability, meeting the demands of a wide range of industries. By continually improving our technology and production processes, we ensure that our partners stay competitive in an increasingly demanding market. The future of rubber track manufacturing lies in the hands of machines that can not only perform but also evolve with industry needs, and Dekuma is proud to be at the forefront of this transformation.