In many industries, the products we rely on are exposed to challenging conditions—extreme temperatures, harsh chemicals, and mechanical stress that can lead to failure. As custom rubber manufacturers, it’s our responsibility to create solutions that not only survive but thrive under these tough conditions. At Dekuma, we’ve spent years perfecting molded rubber products that provide the durability and performance necessary to keep systems running smoothly in harsh environments. Here’s how we address the unique design and material challenges we face in the industry.

The Role of Material Selection in Harsh Conditions

One of the most important aspects of designing molded rubber products for tough environments is selecting the right materials. Different industries, from automotive to energy, require rubber components to withstand high temperatures, exposure to chemicals, and constant mechanical wear. That’s why, at Dekuma, we go above and beyond to choose the most durable and heat-resistant rubber compounds available.

Our custom rubber manufacturers work closely with clients to understand the specific environmental demands they face, allowing us to recommend the best materials for the job. Whether it’s high-temperature resistance, flexibility, or chemical resistance, our team ensures that the material selection process results in products that are capable of handling the most challenging conditions.

Innovative Design Solutions for Extreme Durability

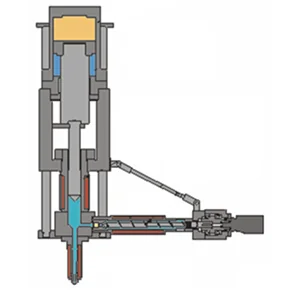

When it comes to creating molded rubber products that endure extreme environments, design is just as crucial as the material. Dekuma takes pride in our innovative approach to design, ensuring that every product is optimized for performance, durability, and efficiency. We utilize advanced techniques like modular designs that allow for customization based on the client’s exact specifications.

For example, we build flexible systems that can handle high-pressure situations, high-impact applications, and extreme temperatures. By focusing on robust designs, we ensure that every molded rubber product from Dekuma can perform consistently, even under the most difficult conditions.

Overcoming Chemical Exposure and Mechanical Stress

In many industrial applications, molded rubber products are exposed to chemicals that can cause degradation or subjected to mechanical stress that wears down materials over time. This makes it crucial for custom rubber manufacturers like us to incorporate materials that resist these challenges. Whether it’s the automotive, energy, or chemical industries, the components we create need to stand up to some of the toughest conditions.

At Dekuma, we utilize specialized rubbers and design features that resist chemical exposure and mechanical wear. This ensures that the molded rubber products we manufacture maintain their functionality and reliability throughout their entire lifecycle, offering superior performance where others might fail.

Conclusion

In conclusion, Dekuma continues to be at the forefront of innovation when it comes to designing and manufacturing molded rubber products for extreme environments. By focusing on the selection of high-quality materials, implementing cutting-edge design strategies, and using advanced technology, we deliver products that stand up to the most demanding conditions. Whether you need to withstand heat, chemicals, or mechanical wear, Dekuma provides tailored, custom solutions that ensure your operations run smoothly and efficiently.