Rubber molding plays an essential role in industries ranging from automotive to agriculture, allowing for the creation of custom rubber components tailored to specific needs. At Dekuma, we understand the intricacies of this process, particularly when it comes to custom rubber molding. Our custom rubber machines are designed to ensure that your production runs smoothly, efficiently, and delivers high-quality results. In this article, we’ll walk through the core steps involved in rubber molding and how our equipment supports each stage to create the best possible products.

The Role of Plasticizing and Injection in Rubber Molding

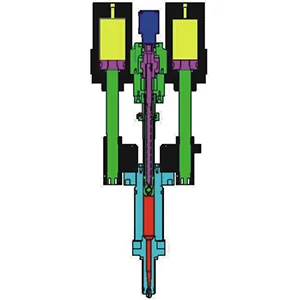

The process begins with plasticizing and injecting the raw rubber into the mold. At Dekuma, our custom rubber molding machines are equipped with an advanced plasticization and injection system, optimized by German technical experts. The injection system is designed to slow down just before the plasticizing process is complete, ensuring a seamless and efficient molding operation. With three adjustable injection zones and separate dwell zones, our machines ensure precise control over the pressure and speed during injection, ensuring that each rubber part meets the required specifications.

The Importance of Clamping System and Mold Stability

One of the critical factors in successful rubber molding is ensuring that the mold remains stable during the entire process. Our custom rubber machines use finite element stress analysis to design the key components, ensuring that all parts maintain adequate rigidity throughout production. The clamping system in our machines features three adjustable clamping zones, allowing for precise control of pressure and speed. This system guarantees a secure mold hold, preventing any unwanted movement and ensuring a perfect finish for every molded piece.

Temperature Control for Precision and Consistency

Temperature control is another essential factor in achieving high-quality rubber parts. At Dekuma, we utilize separate heat transfer oil systems for both the plasticizing and injection barrels, allowing for independent and precise temperature regulation. This enables consistent results and ensures that every molded rubber part is produced with the desired characteristics. With our custom rubber molding solutions, clients can rely on the ability to control temperature at every stage, from start to finish, ensuring that the rubber material behaves exactly as required.

Conclusion

At Dekuma, our custom rubber molding machines are more than just tools; they are solutions designed to meet your specific needs. Our team of experts is committed to providing the most effective and efficient custom rubber machine systems, tailored to optimize your production processes. By offering precise control over injection, clamping, and temperature, our machines ensure top-notch performance and reliability, making us a trusted partner in custom rubber molding. Ready to take your production to the next level? Let’s talk about how Dekuma can help you build the right rubber molding solution for your business.