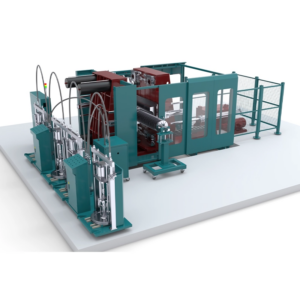

At Dekuma, we are committed to delivering innovative solutions for the manufacturing industry, particularly through our innovative liquid silicone rubber injection molding machines. Our commitment to quality and technology has established us as a leader in the production of high-precision LSR injection molding machines. By providing our clients with advanced solutions, we empower businesses to meet the ever-evolving demands of consumer products.

Revolutionizing Product Development with LSR Technology

The versatility of our China LSR injection molding machines enables manufacturers to explore new horizons in product development. Liquid silicone rubber offers unique properties, such as flexibility, heat resistance, and durability, making it an ideal choice for a wide range of consumer applications. With our liquid silicone rubber injection molding machine, businesses can create products that are not only innovative but also exceed customer expectations in quality and performance.

Our LSR machines incorporate advanced technology, including the S98 smart B&R control system and a user-friendly 10.4-inch color display. These features ensure seamless operation and minimal downtime, allowing companies to focus on creativity and innovation. By leveraging Dekuma’s machines, manufacturers can expedite their production processes and bring new products to market faster than ever.

Achieving Consistency and Quality in Production

Consistency and quality are critical factors in driving innovation in consumer products. With Dekuma’s LSR injection molding machines, we offer high precision and quality assurance at every step of the production cycle. Our patented synchronized dosing devices ensure accurate measurement of raw materials, resulting in uniformity across each batch. This level of quality control is essential for businesses looking to strengthen their brand reputation and build consumer trust.

Moreover, the high-quality static mixers in our liquid silicone rubber injection molding machines guarantee an even mixture of materials, enabling manufacturers to produce reliable and safe consumer products. Whether it’s in the electronics, healthcare, or kitchenware sectors, our machines deliver products that stand out in quality and innovation.

Expanding Market Possibilities

By choosing Dekuma’s China LSR injection molding machine, businesses are not just investing in advanced technology; they are also unlocking a world of market possibilities. The applications for liquid silicone rubber are vast and varied, ranging from kitchen gadgets and children’s toys to medical devices and automotive components. Our machines facilitate the development of products that cater to diverse consumer needs, allowing manufacturers to stay ahead of market trends.

At Dekuma, we understand that innovation is key to maintaining a competitive edge. Our LSR injection molding machines enable our clients to expand their product lines and adapt to shifting consumer preferences swiftly. This dynamic adaptability supports long-term growth and success in a highly competitive marketplace.

Conclusion

By utilizing cutting-edge technology, quality control, and market flexibility, Dekuma-a leading LSR injection molding machine supplier-delivers liquid silicone rubber injection molding machines that propel innovation in consumer goods. Manufacturers may improve their production capacity and maintain their position as industry leaders by utilizing our LSR injection molding equipment. At Dekuma, we look forward to seeing how our technology influences consumer goods in the future as we continue to assist our clients in their pursuit of creative solutions.