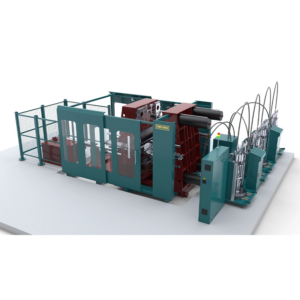

The way rubber components are made by manufacturers has been completely transformed by Dekuma’s rubber injection molding machines. Our rubber molding machine technology guarantees that every part is manufactured with accuracy and efficiency, whether you’re making parts for the electronics industry, automotive components, or ordinary household items. Our injection molding equipment is made to produce excellent results while cutting manufacturing costs, increasing productivity, and eliminating waste. Dekuma’s machines ensure superior product quality while helping producers meet the increasing needs of contemporary industries by providing constant and dependable performance.

Optimized for Versatile Materials

Our Liquid Silicone rubber injection molding machine is specifically designed to handle a wide variety of materials, including TPV, TPE, and flexible modified PVC. These materials are critical in industries ranging from automotive to infant care products. The machine’s advanced dosing system, paired with high-precision mixing, ensures that every injection is accurate and consistent. This makes the machine ideal for producing intricate and delicate items, such as seals, insulators, medical devices, food containers, and more. By accommodating such a broad range of materials, Dekuma’s rubber molding machines offer incredible versatility, allowing manufacturers to produce a diverse array of components with the same high-quality results.

Increased Production Speed with Automation

In today’s fast-paced manufacturing environment, speed and efficiency are crucial to staying competitive. Dekuma’s rubber molding machines incorporate advanced automation to streamline the production process. With the integration of the cutting-edge S98 smart B&R control system, our machines offer enhanced efficiency and reliability, ensuring seamless production cycles. The automation process reduces manual labor, minimizes human error, and allows for continuous, high-speed production. This, in turn, saves valuable time and money while maintaining product consistency. By automating key processes, manufacturers can also scale up production while reducing costs associated with labor and operational delays.

Built for Durability and Efficiency

Durability and efficiency are at the core of Dekuma’s design philosophy. Our injection molding machines are built using world-renowned electrical components and high-quality mechanical systems, ensuring longevity and minimal maintenance. By utilizing the latest technological advancements, we’ve made sure that each machine can withstand the rigors of high-volume production without compromising performance. The combination of robust build quality and advanced features results in a machine that delivers consistent results, reducing the likelihood of faults and downtime. This makes Dekuma’s rubber injection molding equipment a reliable investment for manufacturers seeking to maintain high production levels and product quality over time.

Conclusion

Manufacturers may create accurate, high-quality rubber components for a variety of sectors with the help of Dekuma‘s rubber injection molding equipment. Whether your demands are for consumer goods, automotive parts, or electronics, our injection molding equipment meets manufacturer standards for performance, efficiency, and dependability. Dekuma’s machines assist make sure that your manufacturing processes work smoothly and efficiently, which eventually improves your bottom line. They do this by optimizing material handling, increasing production speed, and being durable.