As the demand for high-quality molded rubber products continues to rise across industries, understanding the importance of certification and meeting industry standards is crucial. For businesses in search of reliable custom rubber manufacturers, Dekuma stands out as a partner dedicated to delivering machines designed for optimal performance, precise product quality, and adherence to global certification requirements.

Understanding Rubber Product Certifications

The certification process for molded rubber products ensures that the products meet essential safety and performance standards. When selecting custom rubber manufacturers, it’s vital to choose a company with a solid reputation for compliance with industry regulations. Dekuma plays an important role in this process, ensuring that every machine produced can manufacture products that pass rigorous testing standards. This certification process ensures that the final molded rubber products are safe, durable, and able to perform to the expectations of industries like automotive, electric, and agriculture.

Certification may vary depending on the application of the molded rubber products. For instance, in industries like medical devices, materials must meet stringent requirements to ensure patient safety. At Dekuma, we integrate these certifications into every machine, so you can trust that your molded rubber products will meet regulatory guidelines, whether they’re designed for sealing systems, gaskets, or other specialized uses.

Why Industry Standards Matter

Industry standards are crucial for any manufacturer producing molded rubber products because they define the levels of safety, durability, and performance required for a product to be deemed acceptable for use in various applications. These standards are determined by organizations like the International Organization for Standardization (ISO), and they help ensure that products are safe, reliable, and functional under specific conditions.

For Dekuma, maintaining compliance with industry standards is at the heart of our operations. Our machines are designed to create molded rubber products that meet and exceed the necessary certifications. From the materials used in the rubber molding process to the final inspection, we follow every necessary step to ensure our products are up to par with international requirements, giving you confidence in the end product’s quality.

Custom Rubber Manufacturing Process and Quality Control

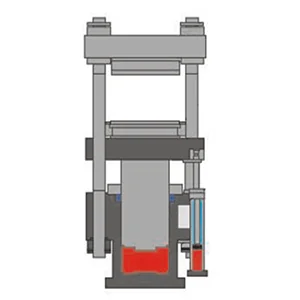

The manufacturing process for molded rubber products is complex, requiring precision and attention to detail to meet the highest standards. At Dekuma, we focus on producing machines with customizable options that allow for maximum flexibility in meeting the specific needs of our customers. By utilizing advanced technologies and incorporating continuous quality control, we ensure that each machine is capable of producing molded rubber products that are consistent and reliable.

We also integrate several quality control checkpoints in our manufacturing process to catch any potential issues before they impact the final product. This thorough approach guarantees that every batch of molded rubber products meets the necessary certification standards. From the initial stages of design to the final product testing, Dekuma’s machines are built with precision and quality in mind, ensuring that your molded rubber products are always of the highest quality.

Conclusion

At Dekuma, we understand that certification and industry standards are critical in the production of high-quality molded rubber products. Our machines are designed to meet and exceed global certifications, ensuring that your rubber products are reliable, durable, and safe for use in a wide range of industries. By choosing Dekuma, you gain a partner committed to quality and compliance, giving you the confidence that your custom rubber products are made with the highest level of precision and care. Whether you are producing seals, gaskets, or other rubber components, we are here to help you achieve exceptional results every time.